ZIGAA

Zigaa Technologies is a leader in high-precision sheet metal processing and laser cutting, focusing on providing comprehensive one-stop services that integrate modern technology with engineering expertise. We specialize in utilizing advanced CNC machinery and laser systems to create intricate and complex workpieces, ranging from heavy industrial steel structures to exquisite architectural CNC Jali patterns. By utilizing world-class design software and selecting premium-grade materials, we have earned the trust of diverse clients who require metalwork that meets both functional demands and long-term durability.

Guided by our philosophy of prioritizing customer satisfaction, we pay close attention to every detail—from the initial consultation and 2D/3D conceptual design to timely production and delivery. Zigaa Technologies is not merely a contract manufacturer; we position ourselves as a business partner ready to support our clients’ ideas and transform them into perfect reality. Whether it is a small-scale project or mass production for industry, we are committed to elevating metalworking standards through modern innovation and services that exceed expectations, ensuring sustainable growth alongside our customers.

Read more

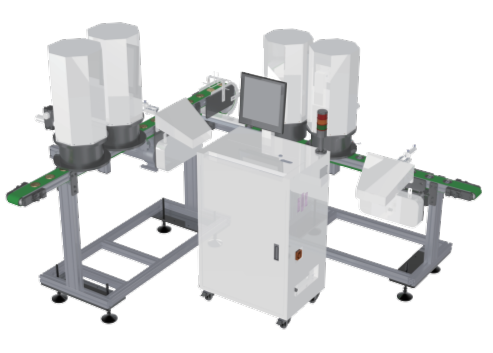

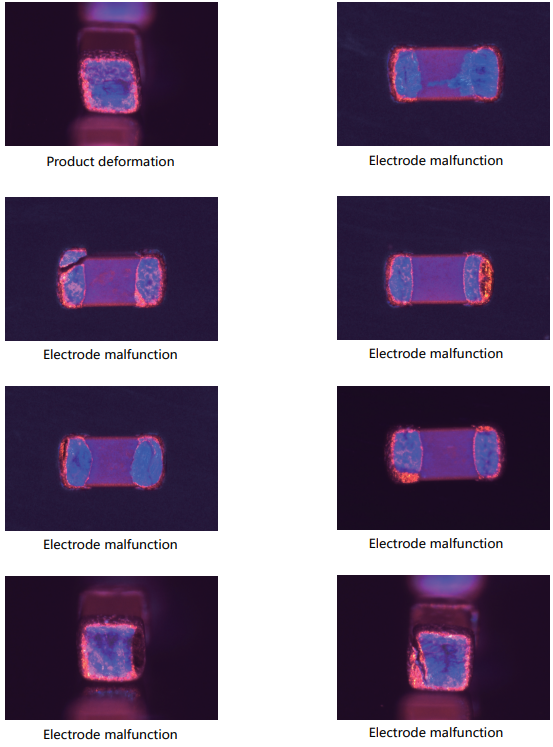

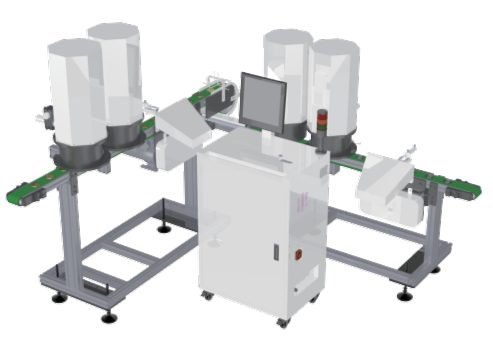

Zigaa MLCC Inspection Equipment

Zigaa MLCC Inspection Equipment (Model: ZG-BDT-MLCC-A-AB-B) is an advanced innovation for automated quality inspection of Multi-Layer Ceramic Capacitors (MLCC), primarily focusing on precision and high speed. The machine is equipped with intelligent AI technology (AI appearance defect detection) capable of thoroughly detecting visual defects, including product dimension deviations, electrode defects, surface cracks, or even minor dirt and deformations. This ensures that every piece inspected meets the highest quality standards before reaching the customer.

In terms of performance, this model is designed to support large-scale production lines with an inspection speed of up to 10,000 pieces per minute. It relies on the integration of high-speed industrial cameras and a specialized lighting system (360/180 ROI dual-color light source), enabling comprehensive analysis of the workpiece from every angle. Powered by a high-performance DELL processing system and featuring a stable automated feeding system, Zigaa MLCC Inspection Equipment is the ideal solution for electronic component manufacturers looking to enhance quality control efficiency and effectively minimize the escape rate of substandard products.

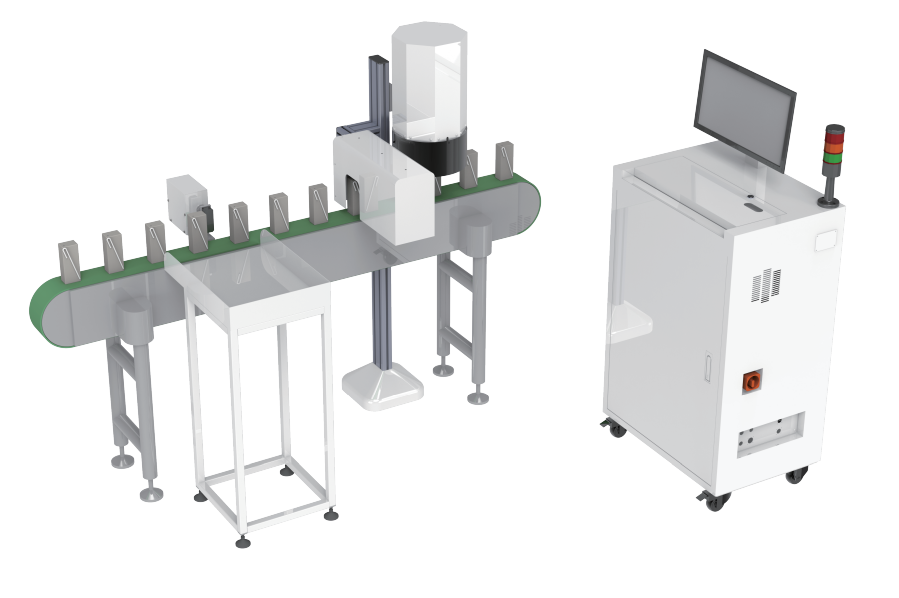

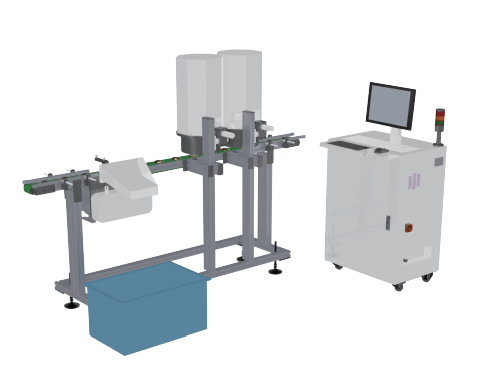

Liplet Pack Inspection Equipment

The Liplet Pack Inspection Equipment is an intelligent conveyor-based quality inspection system designed to elevate production standards within the consumer goods and beverage industries. This system specializes in the detailed integrity inspection of Libero bag packaging, precisely detecting common defects such as missing or misaligned straws (No straw/Straw offset), missing covers (No cover), and incorrect or missing product codes (No code/Miss code), as well as smudged or misplaced coding. Utilizing an advanced visual inspection system, it ensures that every product leaving the production line is flawless and displays accurate, complete information.

In terms of performance and technical features, this machine supports high-speed operations of up to 1,000 pieces per minute, significantly boosting production efficiency without causing bottlenecks. The equipment features a compact control cabinet and a highly stable camera station, capable of operating in environments ranging from 0-50°C with a low power consumption of only 1.2kW. Designed for easy inline integration with existing conveyor belts, the Liplet Pack Inspection Equipment is a cost-effective choice for factories seeking a precise, automated quality control system that meets the demands of modern manufacturing.

Technical Highlights:

-

Inspection Speed: 1,000 pieces/min

-

Detectable Defects: Coding errors (Code), straw issues (Straw), dirt/smudges, and other packaging anomalies

-

Machine Weight: 200 kg

-

Power: AC 220V, 1.2kW

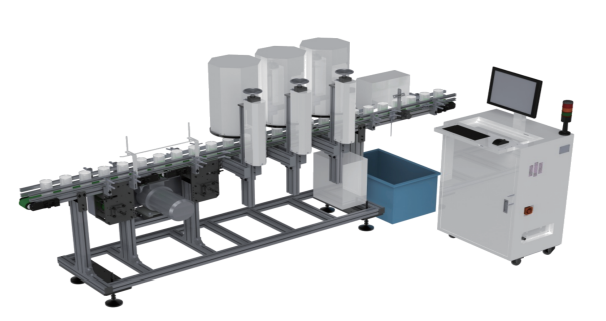

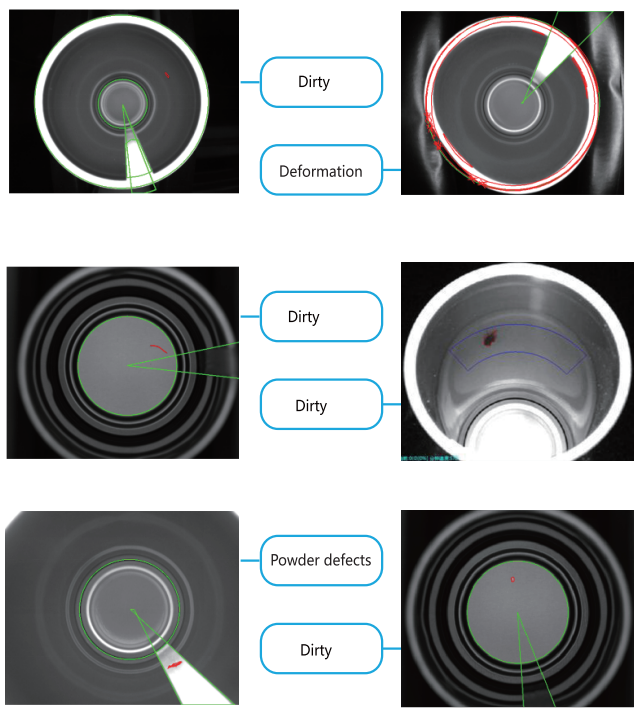

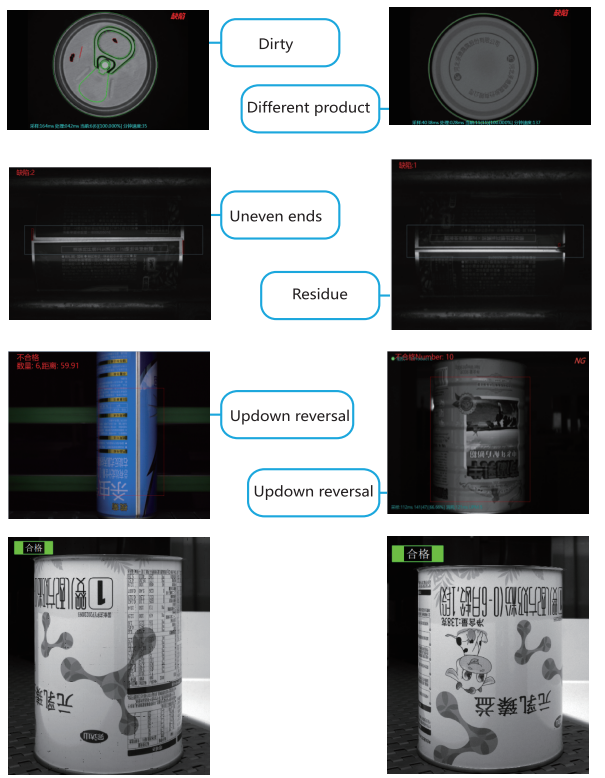

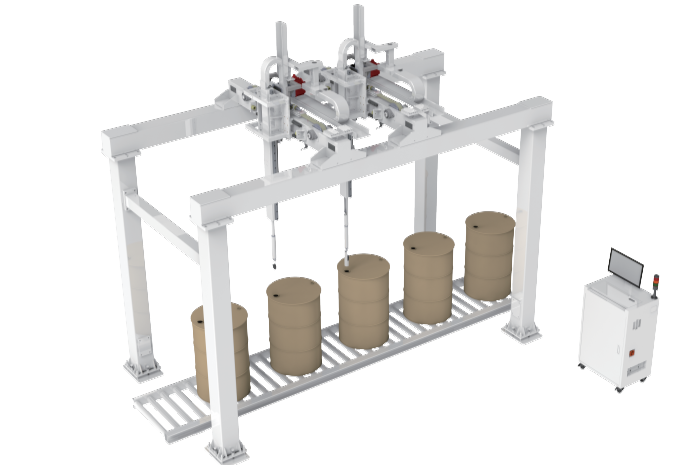

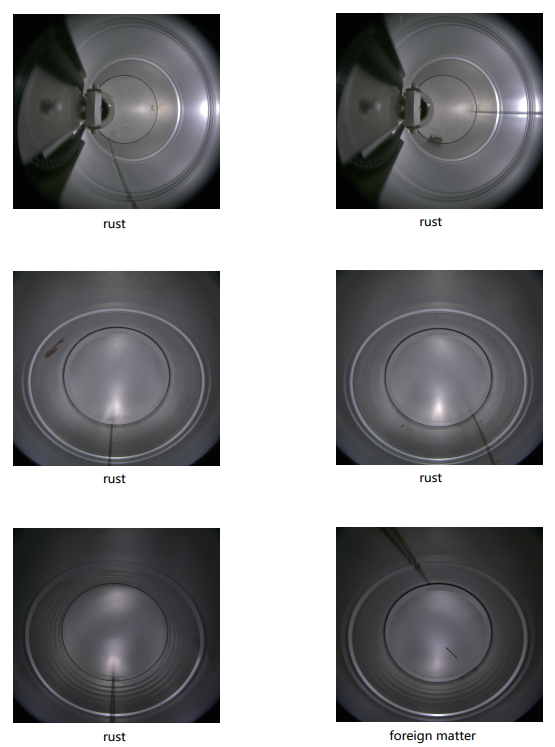

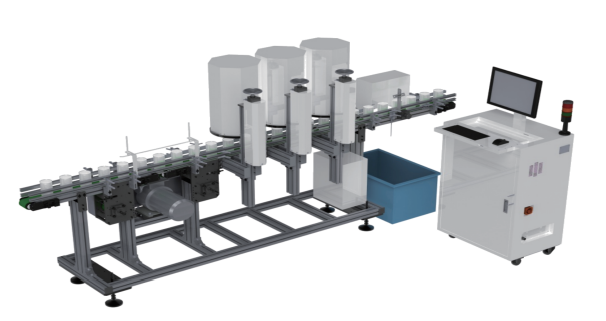

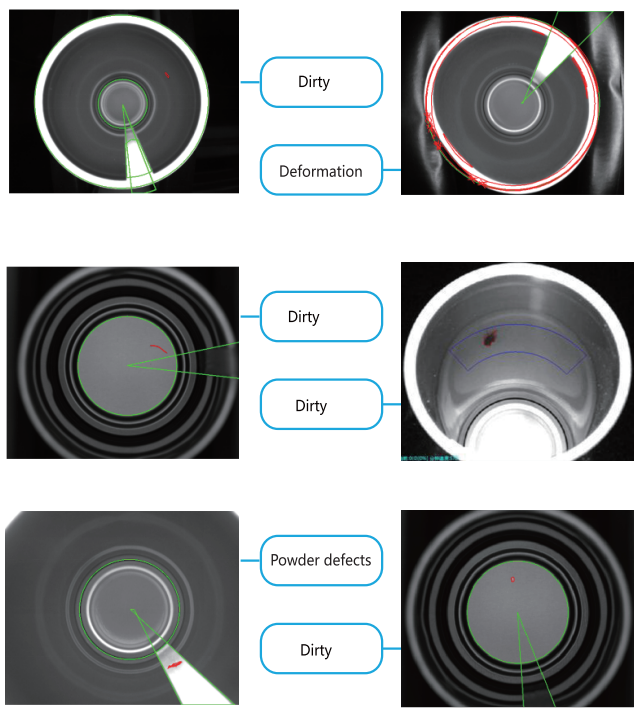

Steel Barrel Inspection Equipment

The Steel Barrel Inspection Equipment is an advanced quality control solution specifically designed to address cleanliness and packaging integrity for steel drums. Its primary function is the detection of foreign bodies inside the barrel, as well as the inspection of rust spots and structural deformations. Utilizing high-precision image processing technology, the system provides a clear view of the interior—even in hard-to-reach areas—reducing the risk of contamination and enhancing safety standards for contained products such as chemicals or industrial oils.

In terms of technical performance, this model supports an inspection speed of 20 units per minute, making it ideal for integration into continuous production lines. The system consists of a large-scale inspection station (1300 x 1800 x 2800 mm) and a separate control cabinet, operating with a power consumption of 1.2kW. With a robust structural design and a machine weight of approximately 300 kg, the Steel Barrel Inspection Equipment from ZiGAA is an essential tool that ensures every steel drum is 100% clean, intact, and ready for use.

Technical Highlights:

-

Primary Purpose: Detection of foreign objects, rust, and deformation in steel barrels.

-

Operating Speed: 20 barrels/min

-

Detection Capability: Clearly identifies issues, even small rust spots or foreign debris at the bottom of the barrel.

-

Power Consumption: AC 220V, 1.2kW

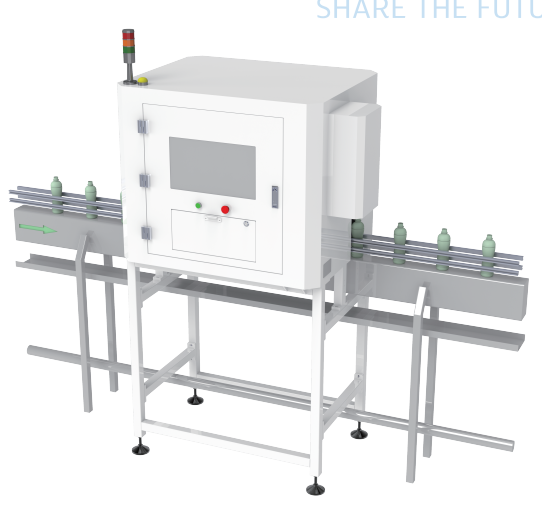

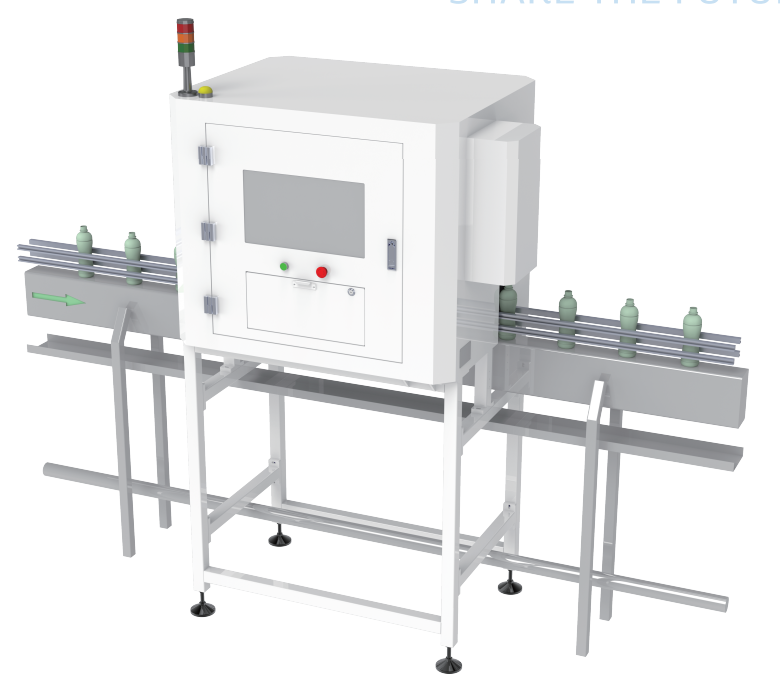

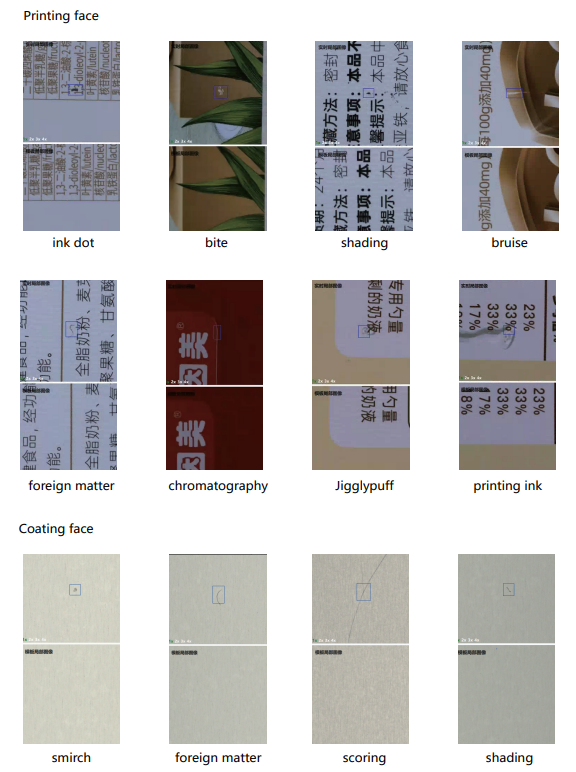

PET Bottle High Tilt Cover + Liquid Level Detection

The PET Bottle High Tilt Cover + Liquid Level Detection is an intelligent quality inspection technology designed for PET bottled beverage production lines. It focuses on precisely verifying the integrity of the bottle cap and the liquid level inside. The system comprehensively detects defects that could impact product quality, such as high or crooked lids (High lid/Crooked lid), missing lids (No lid), broken or missing safety rings (Missing safety ring/No safety ring), and product levels that are higher or lower than the standard (High/Low level). This ensures the prevention of leakage and maintains a professional brand image before the product reaches the consumer.

In terms of operation, this model features a high inspection efficiency of up to 1,000 pieces per minute, making it ideal for high-speed production lines. The equipment consists of a Visual Camera Station and a robustly designed control cabinet, capable of operating in factory environments with temperatures ranging from 0–50°C. It consumes only 1.2kW of power and has a total machine weight of 470 kg. With fast and accurate image processing technology, this inspection system from ZiGAA is a vital tool for reducing waste and significantly increasing confidence in automated bottling processes.

Technical Highlights:

-

Inspection Speed: 1,000 pieces/min

-

Detectable Defects: Liquid level, crooked lids, loose lids, missing or broken safety rings, and missing lids

-

Machine Weight: 470 kg

-

Power: AC 220V, 1.2kW

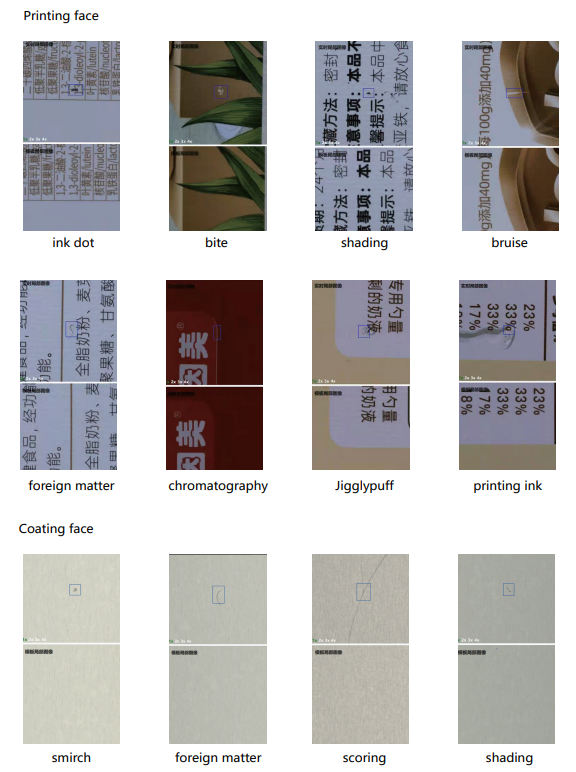

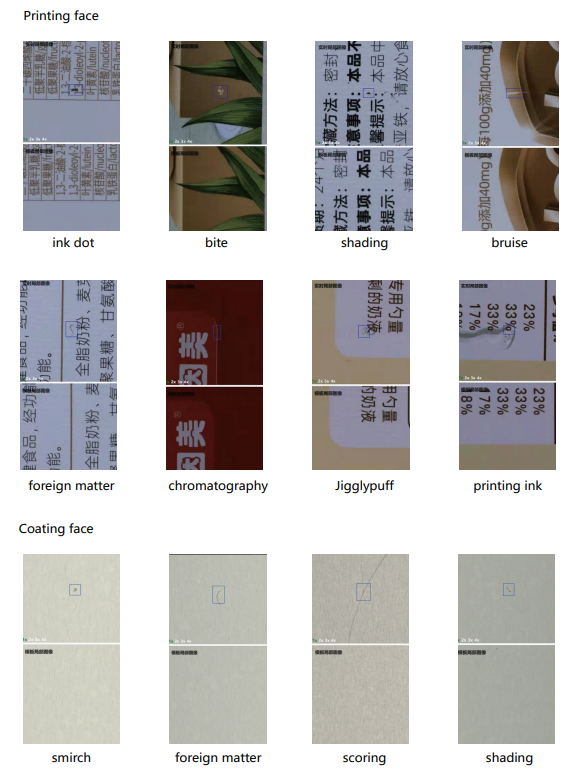

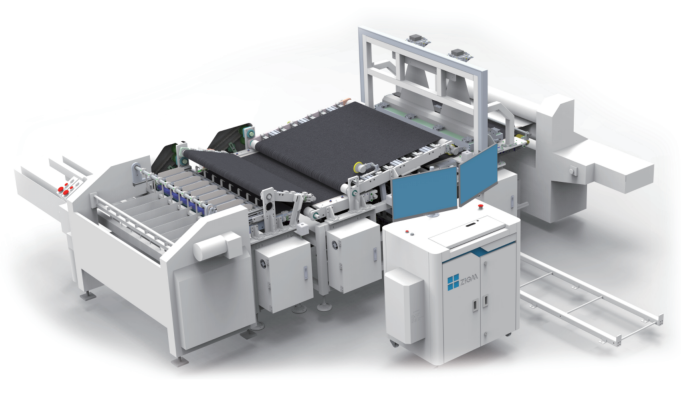

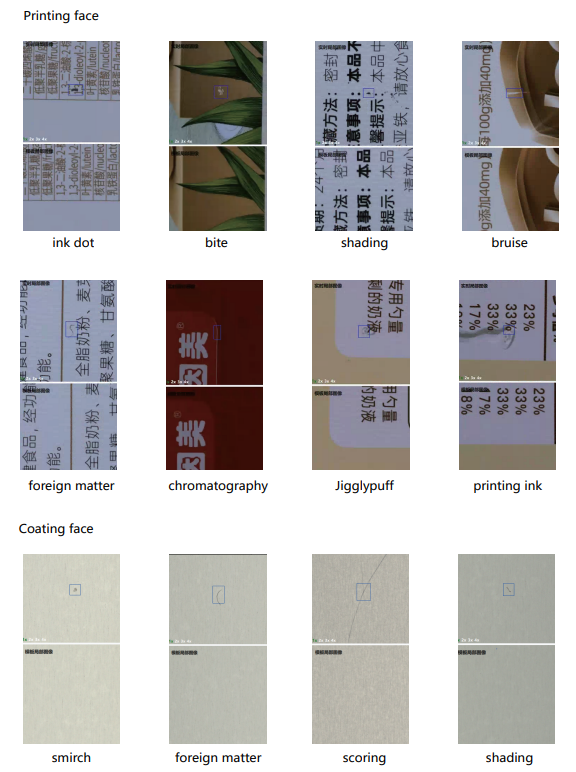

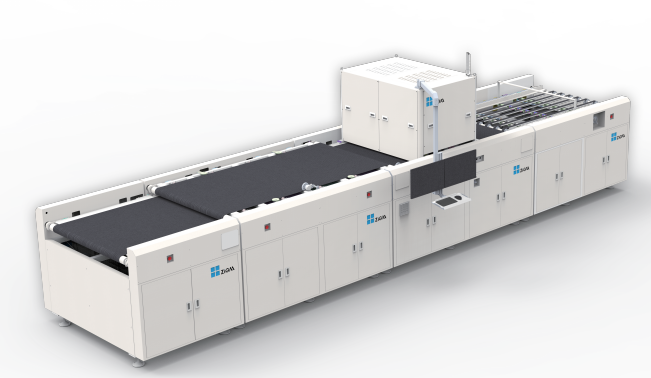

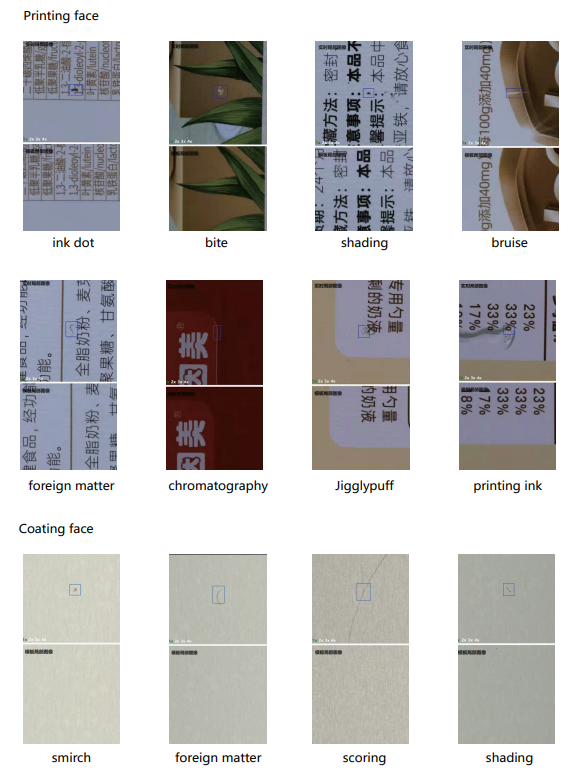

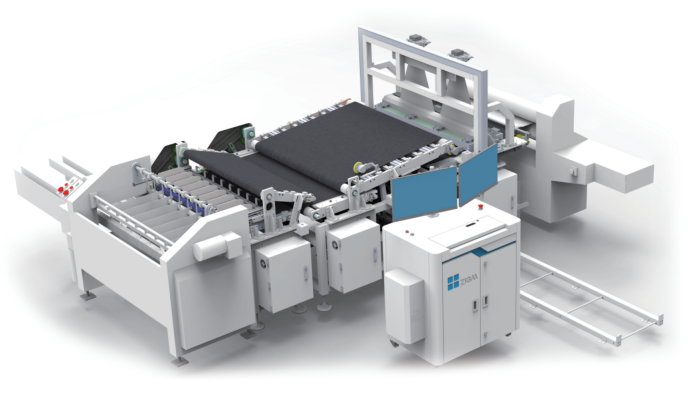

OFFLINE SHEET INSPECTION EQUIPMENT

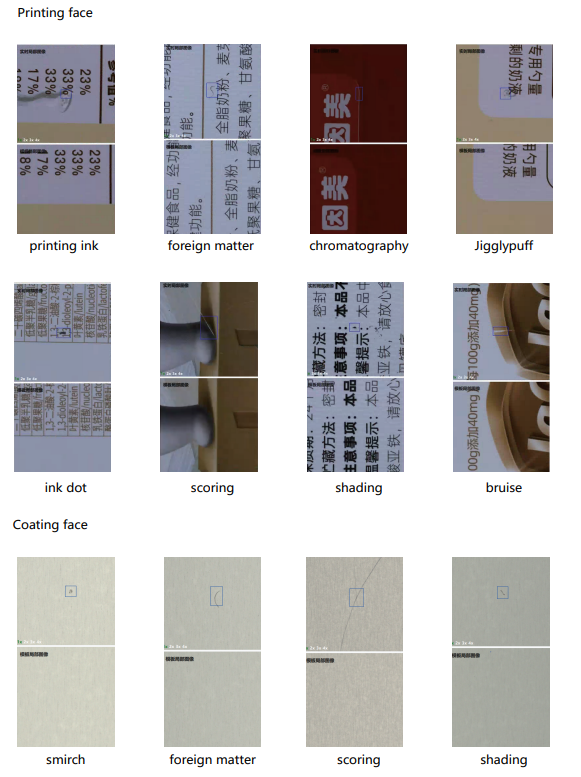

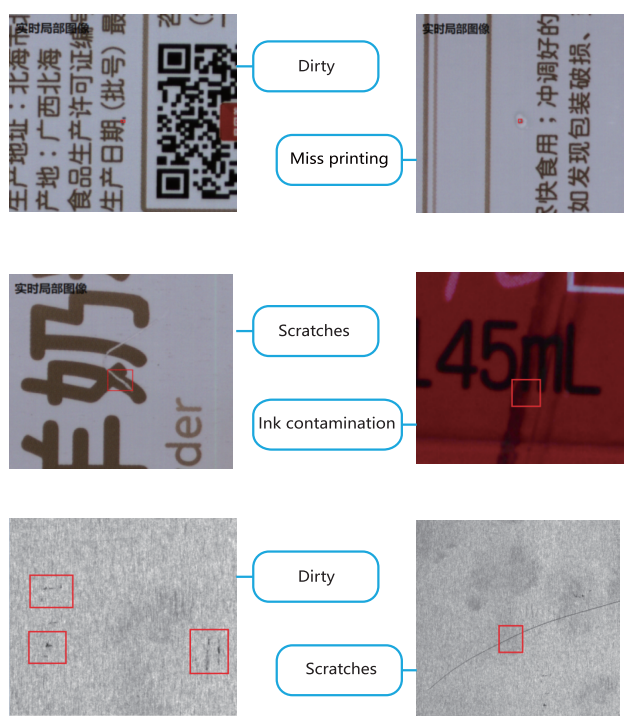

The Sheet Inspection Equipment is a high-performance quality inspection system designed for the meticulous control of printing and coating standards. This system offers comprehensive surface defect detection, divided into two primary areas: the Printing face, which identifies ink spots, overprints, scratches, color differences, and errors in text or patterns; and the Coating face, which inspects for dirt, scratches, and soot. This ensures that every sheet is perfectly finished on both sides before proceeding to the next stage of production.

In terms of technical performance, this machine supports an inspection speed of up to 120 meters per minute. It is equipped with a Visual Camera Station and a standard electrical control cabinet. The unit has a total weight of 470 kg, operates on 1.2kW of power, and maintains stability in factory environments with temperatures ranging from 0–50°C. With its precise image analysis technology, the Sheet Inspection Equipment is a vital solution for reducing waste in the printing process and significantly enhancing industrial-scale production efficiency.

Technical Highlights:

-

Inspection Speed: 120 meters/min

-

Detectable Defects: Ink spots, color differences, scratches, text errors, and dirt on the coating surface

-

Machine Weight: 470 kg

-

Power: AC 220V, 1.2kW

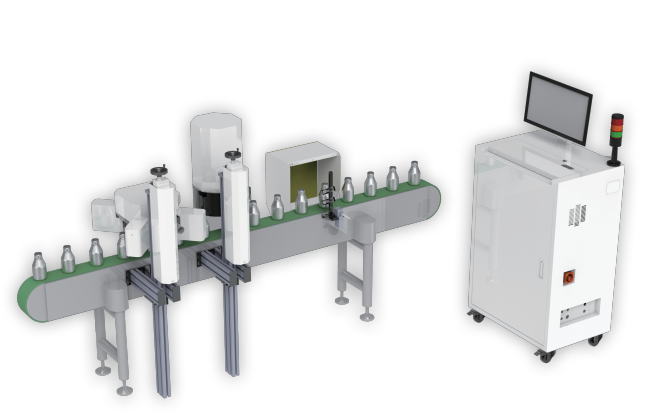

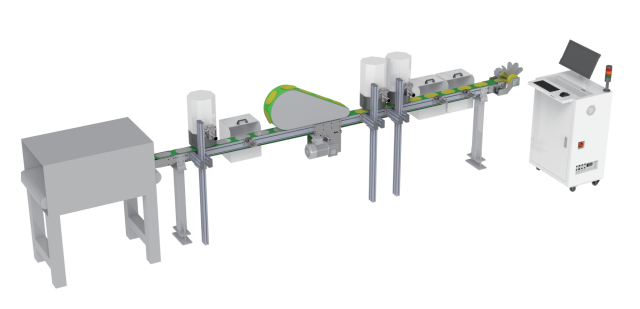

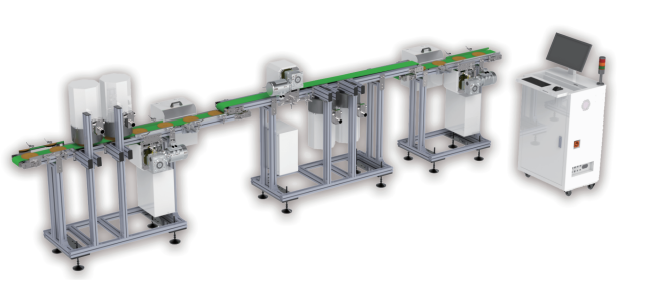

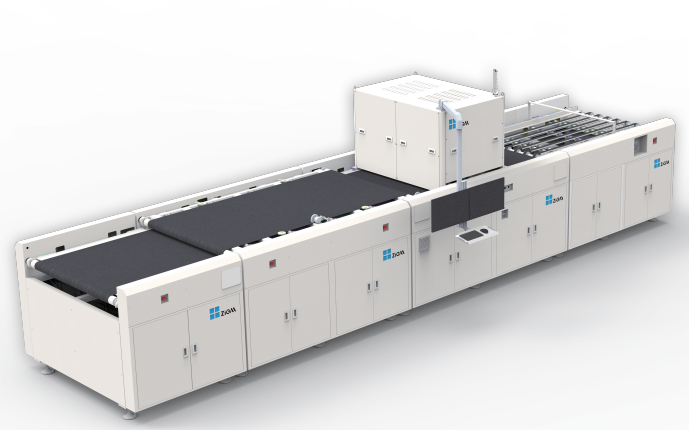

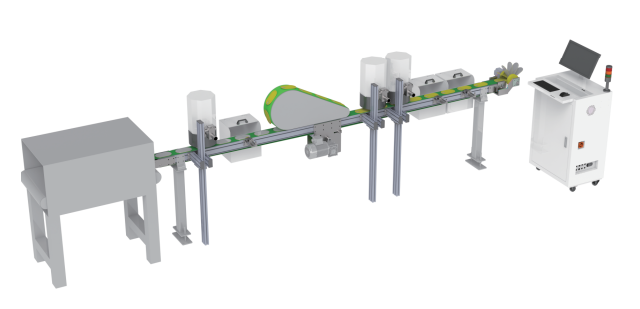

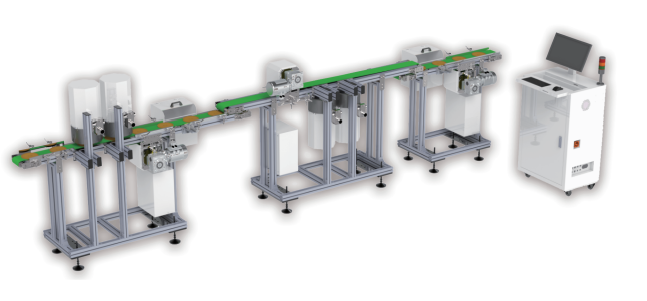

OFFLINE BLANK INSPECTION EQUIPMENT

The Blank Printing and Coating Inspection Equipment is the most powerful inline quality inspection system in this series. It is designed to detect printing and coating anomalies at very high speeds, providing detailed double-sided inspection:

-

Printing face: Detects ink spots, overprinting, scratches, dirt, ink pull, text/pattern deviation, and severe color differences.

-

Coating face: Inspects for dirt, scratches, soot, and non-standard color variations.

In terms of performance, this machine stands out with a detection speed of at least 180 meters per minute and supports a production efficiency of 150–500 pieces per minute, depending on the dimensions of the workpiece. The system is a large-scale machine with a total length exceeding 7 meters, featuring an integrated feeding machine and a comprehensive inspection platform. It operates on 15KW of power and supports an industrial voltage of 380V AC, making it the ideal solution for packaging plants or industrial-scale printing houses that demand the strictest and fastest quality control.

Technical Highlights:

-

Conveyor Speed: ± 180 meters/min

-

Inspection Efficiency: 150 – 500 pieces/min

-

Working Voltage: 380V AC ± 10%

-

Machine Dimensions: Length 7,386 mm x Width 2,500 mm x Height 1,800 mm

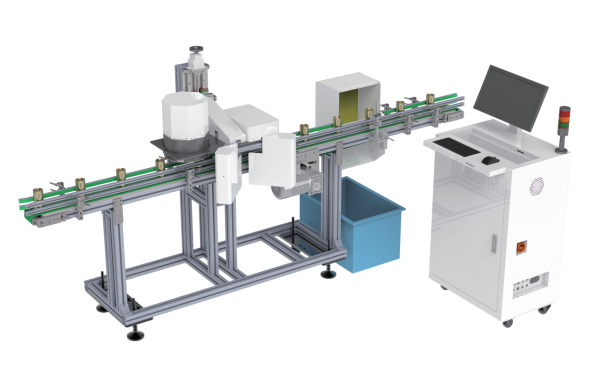

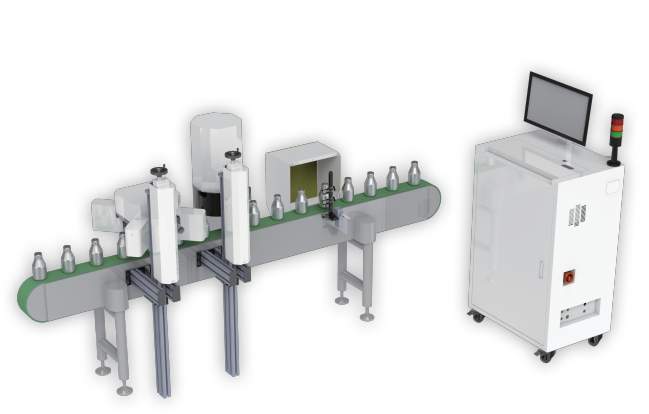

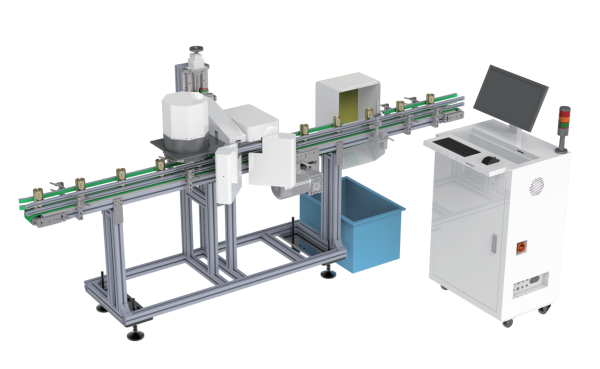

Aluminum Can Inspection Equipment

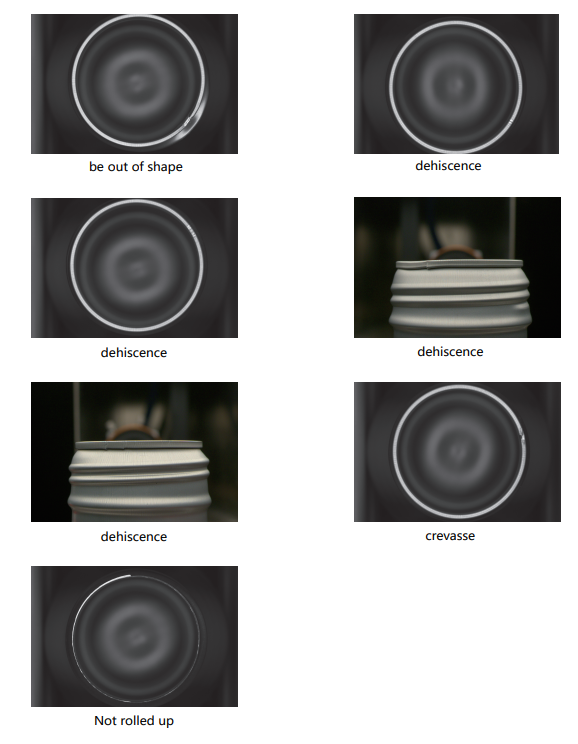

The Aluminum Can Inspection Equipment is a high-precision automated system designed to verify the integrity of aluminum cans by specifically detecting defects that affect packaging quality. The system can identify various critical structural issues, such as cans being out of shape, crevasses on the rim or body, dehiscence, and manufacturing flaws like rims that are not properly rolled up. This ensures that every container is structurally sound and ready for safe product filling.

In terms of technical performance, this model supports production line inspections at a maximum conveyor speed of 120 meters per minute. The machine features a compact, space-saving design with a total weight of only 200 kg. It operates under AC 220V power with a low consumption of just 1.2kW. Additionally, the camera station can be customized to suit specific workpiece sizes, making it a cost-effective choice for factories looking to upgrade quality control standards within limited space while maintaining high production efficiency.

Technical Highlights:

-

Inspection Speed: 120 meters/min

-

Detectable Defects: Deformed cans, dehiscence, crevasses, and incomplete rim rolling

-

Machine Weight: 200 kg

-

Power: AC 220V, 1.2kW

ONLINE SHEET INSPECTION EQUIPMENT

This is an advanced quality inspection system specifically designed for the metal sheet printing industry, such as tinplate or flat steel sheets. The system enhances quality control through automation and precision, allowing for seamless inline integration into existing production lines for real-time workpiece inspection. Utilizing modern image processing technology, it meticulously detects anomalies in both printing and coating across both sides of the material.

In terms of performance, this model supports high-speed production lines with a maximum inspection speed of 180 meters per minute (approximately 110 sheets per minute). The system operates with a total power consumption of 10kW under an industrial voltage of 380V AC. Its structural design offers flexibility based on installation space requirements, ranging from single-sided inspection units to full double-sided systems with a maximum length of 8,000 mm. This ensures that every sheet passing through inspection maintains perfect print quality and meets the highest industry standards.

Defects can be detected:

-

Printing face: Ink spots, overprinting, dirt, ink pull, scratches, pull strips, text/pattern deviation, color difference, and severe color variation.

-

Coating face: Dirt, scratches, soot, and severe color variation.

Technical Highlights:

-

Inspection Speed: 180 m/min (110 sheets/min)

-

Test Content: Inspection of printing on tinplate and flat steel sheets

-

Working Voltage: 380V AC $pm$ 10%

-

Power: 10kW (includes standard production line and inspection equipment)

-

Air Supply: > 0.6MPa

-

Working Environment: 0–45°C (no condensation)

-

Weight/Dimensions: Depending on line configuration (length ranging from 5,800 mm to 8,000 mm)

360 Inspection Equipment

The 360 Inspection Equipment is an automated packaging quality inspection system designed for comprehensive 360-degree external appearance checks. This ensures that every product leaving the production line is perfect from every angle. This system is ideal for the beverage and food packaging industries, which require high precision in controlling print quality and packaging conditions. The machine can detect a wide range of defects in a single step, including dirt/stains, overprinting or printing errors, scratches, ink smears, nicks or chips on the packaging, rust, peeling or distorted colors, deformed packaging, and mixed product types.

In terms of technical performance, this model supports a maximum inspection speed of up to 1,000 pieces per minute, significantly increasing production capacity. The unit features a robust structure and operates on an AC 220V power system. It comes equipped with an intelligent control unit capable of rapidly rejecting substandard workpieces, making it a cost-effective solution for factories focusing on international quality standards.

Technical Highlights:

-

Inspection Speed: 1,000 pieces/min

-

Test Content: 360-degree detection (360 detection)

-

Electrical System: AC 220V

-

Power: 1.2kW

-

Air Pressure: 0.4~0.6MPa

-

Machine Weight: 470 kg

-

Working Environment: 0~50°C (no condensation)

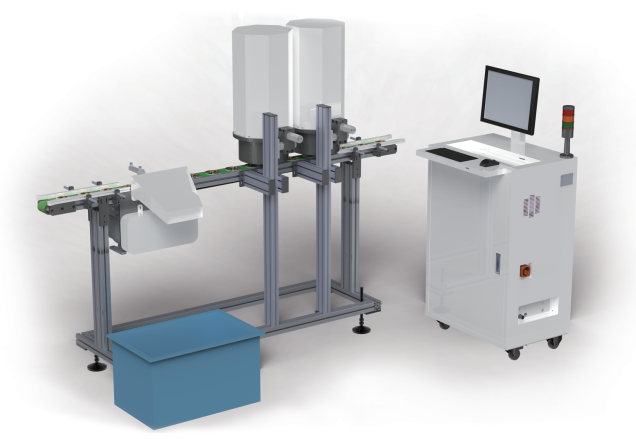

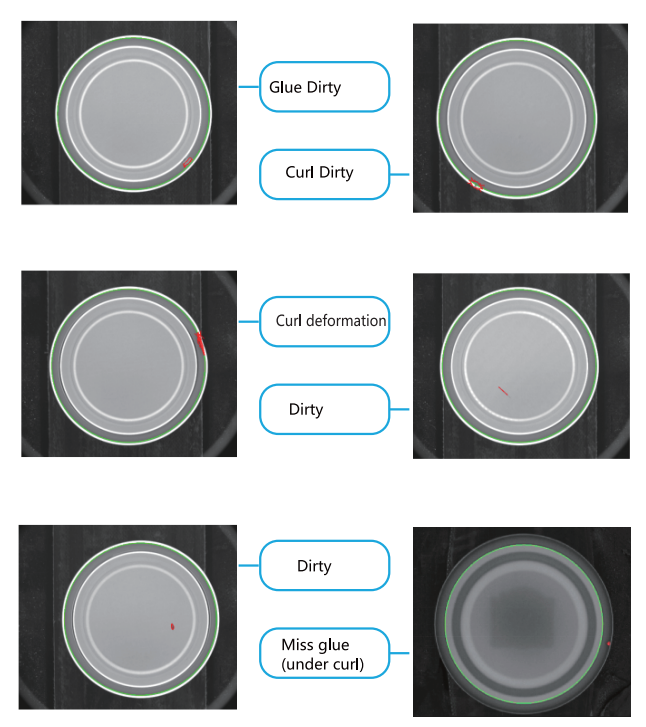

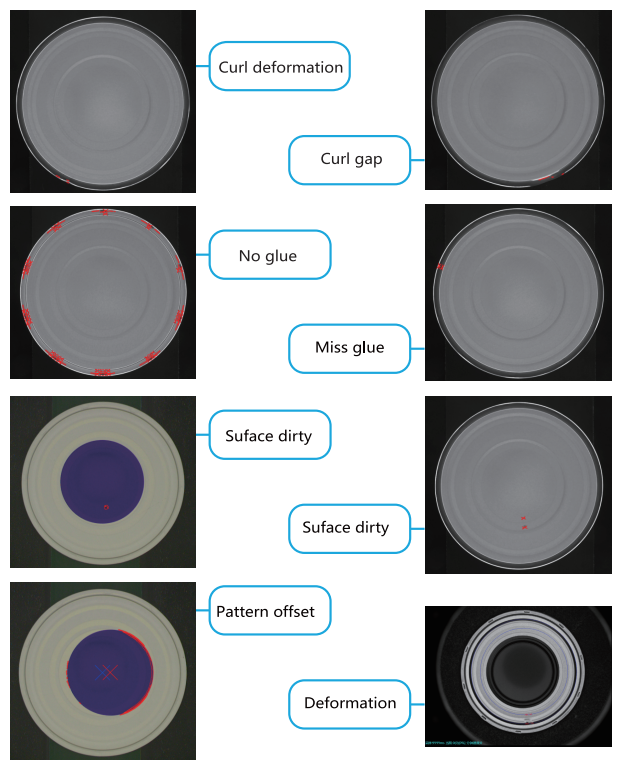

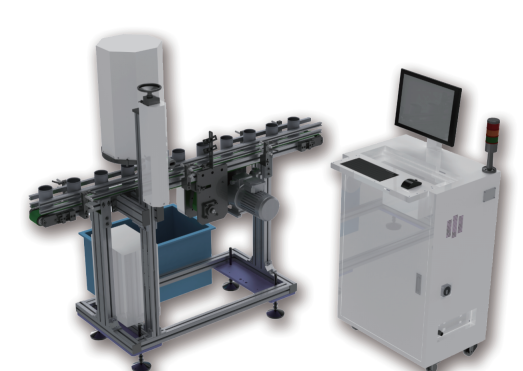

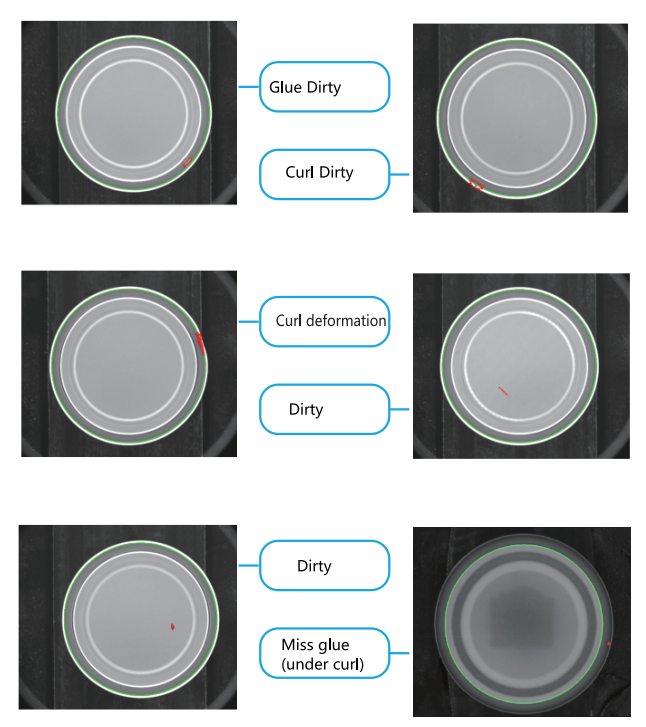

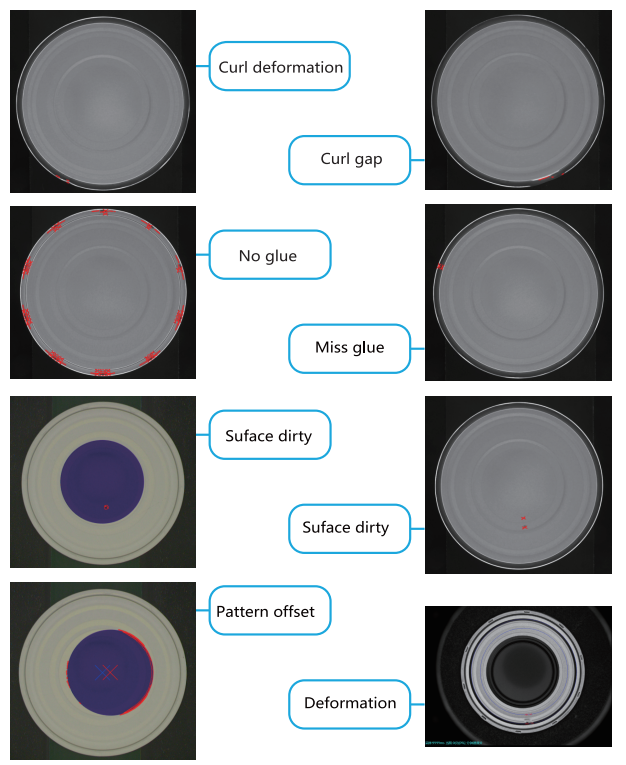

Sanitary Ends Inspection Equipment

The Sanitary Ends Inspection Equipment is an automated quality inspection technology designed to meet the safety and hygiene standards of the metal packaging industry. The system is capable of high-speed inspection at up to 1,500 pieces per minute, ensuring that every lid is perfect in terms of rim curling, glue application, and printing before actual use.

This inspection system is designed for high precision and easy installation with a compact machine structure weighing approximately 130 kg. It can meticulously detect defects in hard-to-see areas, covering rim abnormalities (Curl) such as uncurled edges, deformed edges, or stains; glue application issues (Glue) such as intermittent or missing glue; material surface anomalies; and printing errors (Printing) such as overprinting or missing prints. It also includes the capability to sort and remove incorrect product types from the production line.

Technical Highlights:

-

Inspection Speed: 1,500 pieces/min

-

Inspection Objects: Sanitary Ends packaging lids

-

Electrical System: AC 220V

-

Power: 600W

-

Air Pressure: 0.4~0.6Mpa

-

Machine Weight: Approximately 130 kg

-

Working Environment: 0~50°C (no condensation)

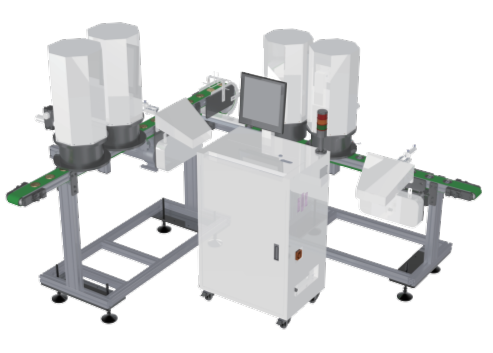

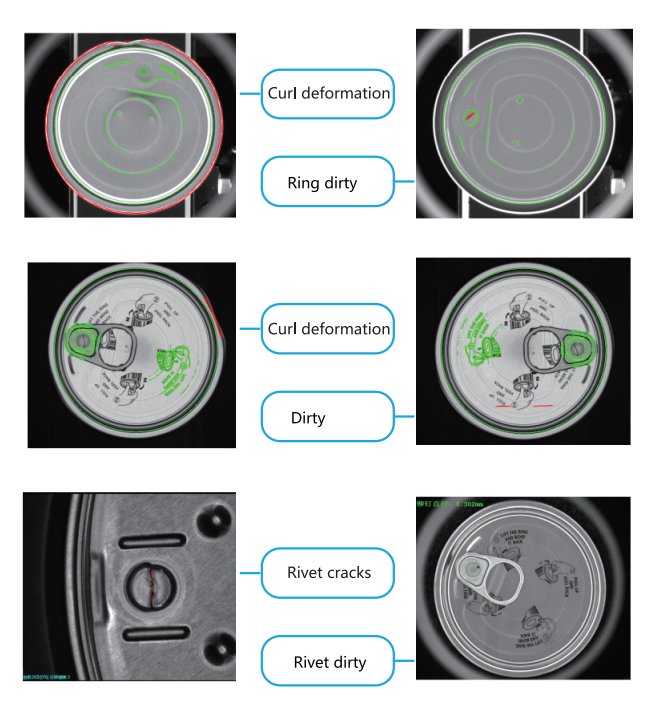

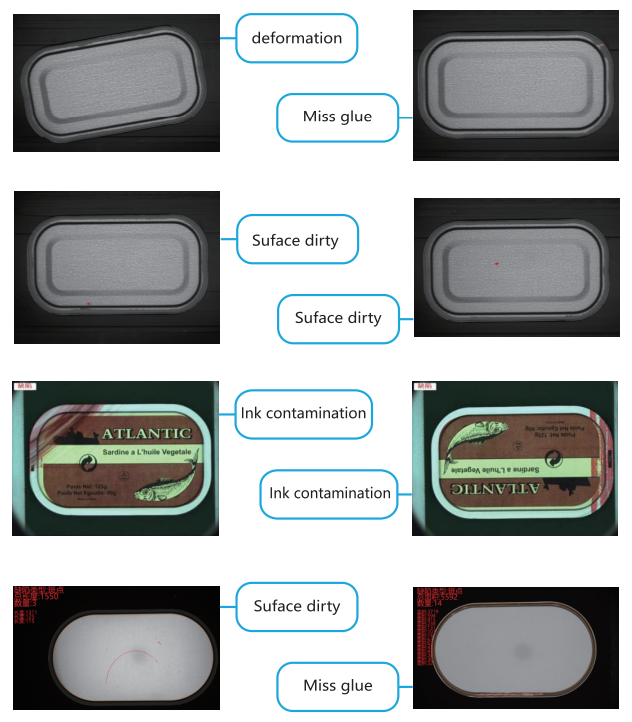

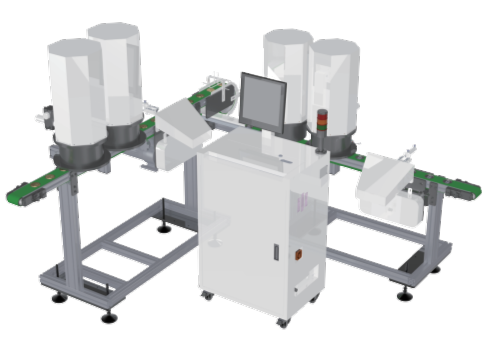

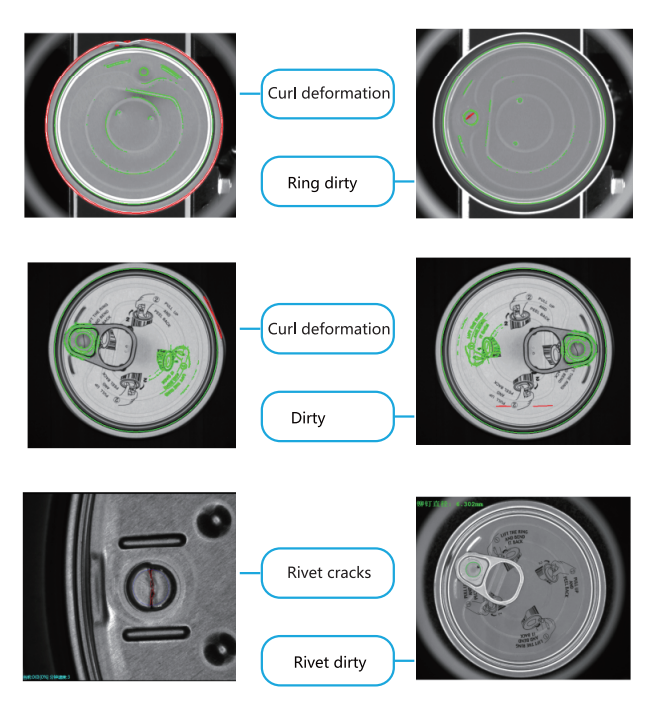

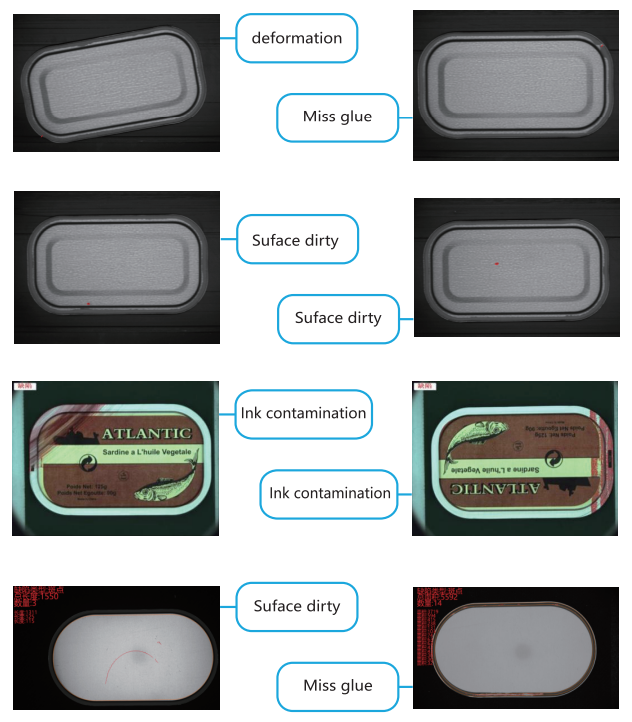

Easy-open Ends Inspection Equipment

The Easy-open Ends Inspection Equipment is an automated system designed for the high-precision and high-speed inspection of easy-open lids. It is specifically engineered to control quality within metal packaging production lines. The system can detect complex defects across all critical points, including the integrity of the curl, glue application, surface and print condition, rivet integrity, pull ring, and groove coating. This comprehensive check prevents leakage and abnormalities before the product reaches the consumer. It identifies a wide range of defects, such as deformed curls, missing glue, cracked rivets, misaligned rings, scratches, dirt, and overprinting.

In terms of performance, the machine supports a maximum inspection speed of 800 pieces per minute. It features a robust yet lightweight structure, weighing only 130 kg, and is energy-efficient with a power consumption of 600W. Its compact design saves installation space, while the precise image processing system allows for the immediate rejection of substandard workpieces. This makes it a cost-effective choice for upgrading quality control standards in industrial plants.

Technical Highlights:

-

Inspection Speed: 800 pieces/min

-

Inspection Objects: Easy-open Ends packaging lids

-

Electrical System: AC 220V

-

Power: 600W

-

Air Pressure: 0.4~0.6Mpa

-

Machine Weight: Approximately 130 kg

-

Working Environment: 0~50°C (no condensation)

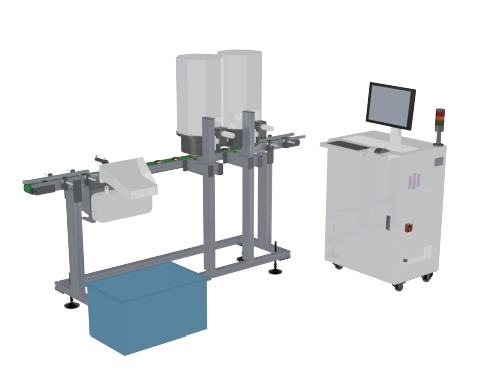

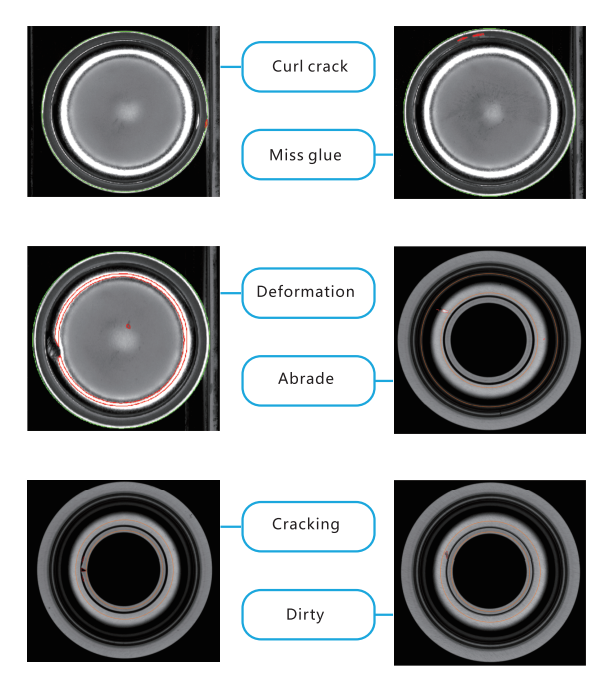

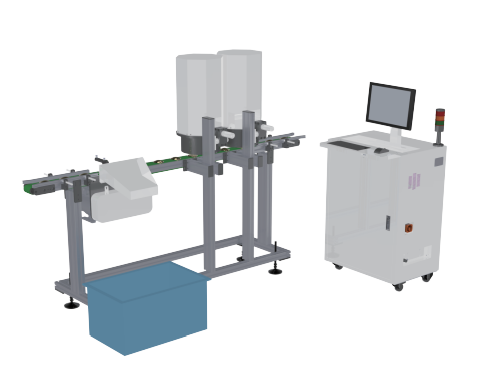

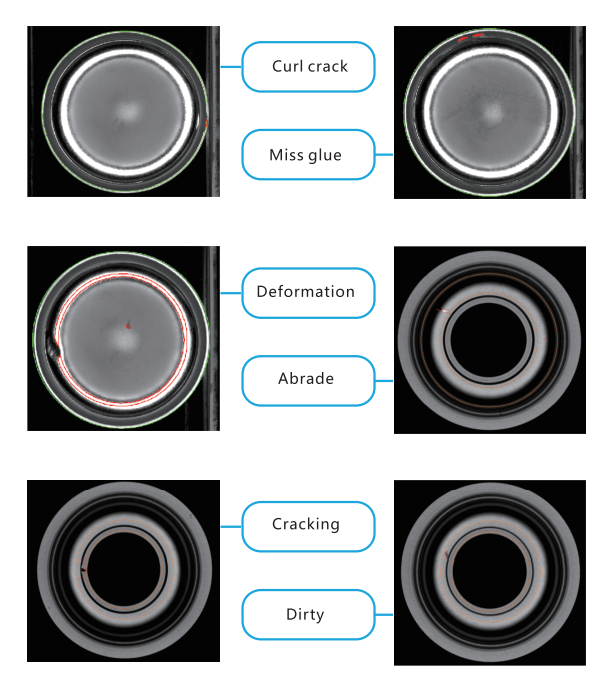

Aerosol Ends Inspection Equipment

The Aerosol Ends Inspection Equipment is an automated quality inspection system for aerosol lids, focusing on high precision and speed to meet the demands of the packaging industry for maximum safety. This system is designed to rapidly reject substandard workpieces from the production line, reducing the risk of leakage or packaging damage that could occur during actual use.

In terms of performance, the machine supports a maximum inspection speed of up to 800 pieces per minute. The system comprehensively detects defects across several critical areas, including the Curl (such as missing curls, deformed edges, or splits), Glue application issues (such as uneven or missing glue), and the Ends surface integrity (to find cracks, wrinkles, or scratches). It also inspects the Up curl to ensure every lid is in 100% ready-to-use condition.

Technical Highlights:

-

Inspection Speed: 800 pieces/min

-

Inspection Objects: Aerosol Ends packaging lids

-

Electrical System: AC 220V

-

Power: 600W

-

Air Pressure: 0.4~0.6Mpa

-

Machine Weight: Approximately 130 kg

-

Working Environment: 0~50°C (no condensation)

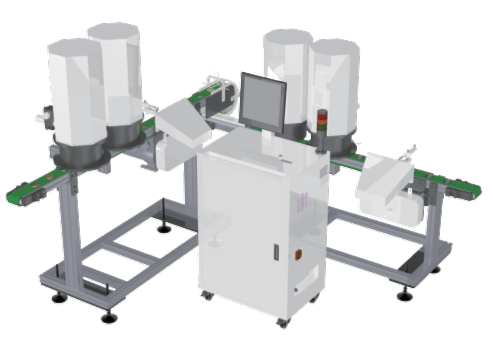

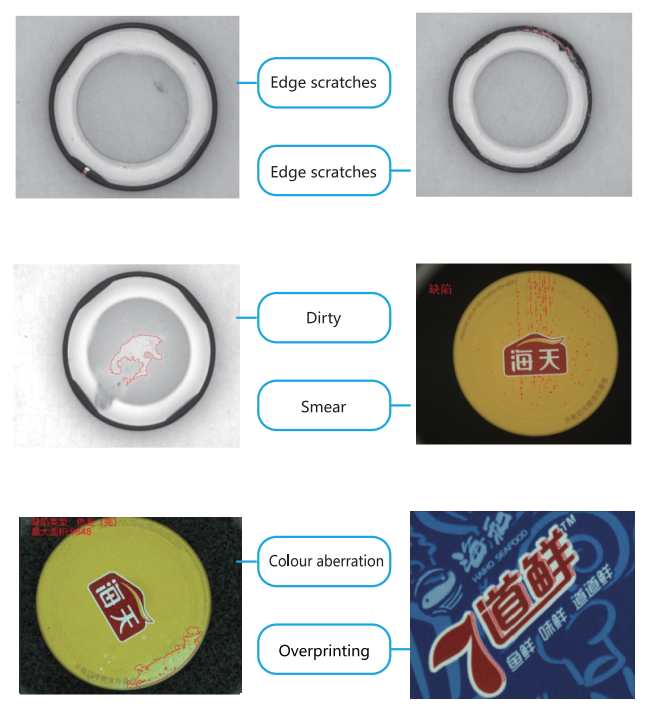

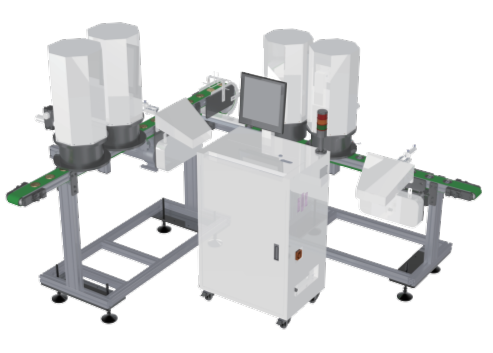

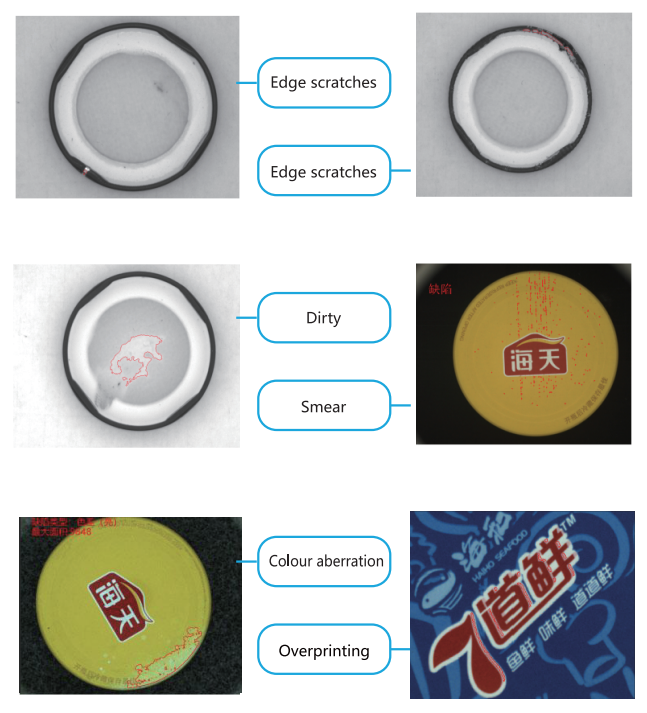

Twist-off Ends Inspection Equipment

Twist-off Ends Inspection Equipment is an automated quality inspection technology for twist-off caps that prioritizes high precision. It is designed to control manufacturing standards for metal lid packaging used in the food and beverage industries. This system utilizes advanced image processing to inspect the integrity of workpieces in every detail, including both the glue application and the printing on the lid surface. This prevents leakage and contamination in bottled products by meticulously detecting defects such as edge scratches, dirt, smears, color aberration, and overprinting, as well as structural issues like deformed lids or missing/intermittent glue.

In terms of performance, the machine supports a maximum inspection speed of 600 pieces per minute. The system is designed for energy efficiency with a power consumption of only 600W and a machine weight of approximately 130 kg, allowing for flexible and space-saving installation within existing production lines. It is built for stable, continuous operation in industrial environments, ensuring that every product delivered to consumers meets the highest quality standards.

Technical Highlights:

-

Inspection Speed: 600 pieces/min

-

Inspection Objects: Twist-off ends packaging lids

-

Detectable Defects: Edge scratches, dirt/smears, color aberration, overprinting/print offset, deformed lids, and glue application issues

-

Machine Weight: Approximately 130 kg

-

Electrical System: AC 220V, Power 600W

-

Air Pressure: 0.4~0.6Mpa

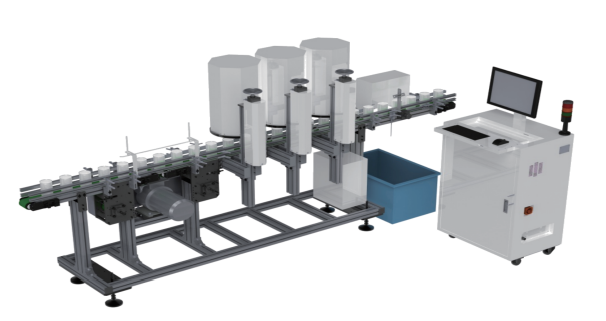

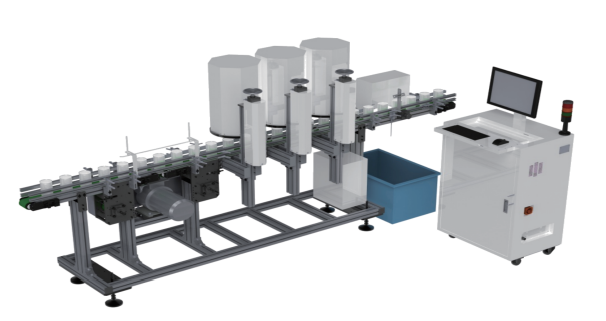

Milk powder cans Inspection Equipment

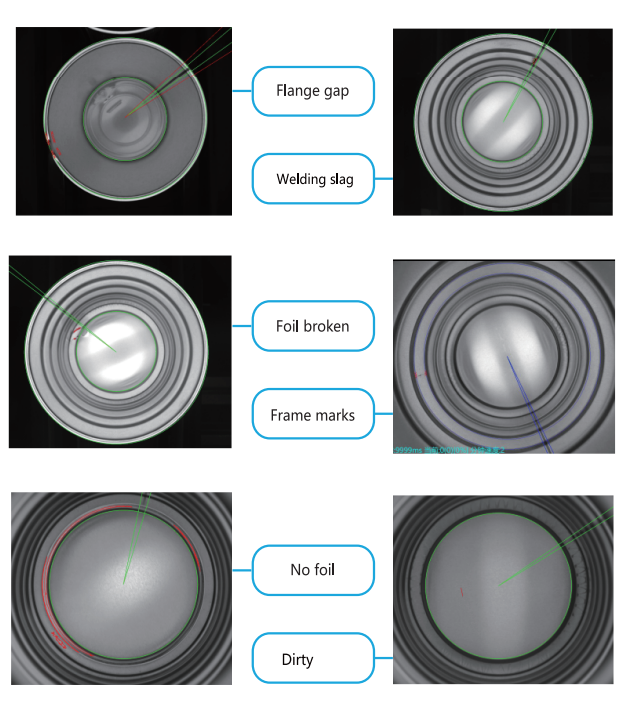

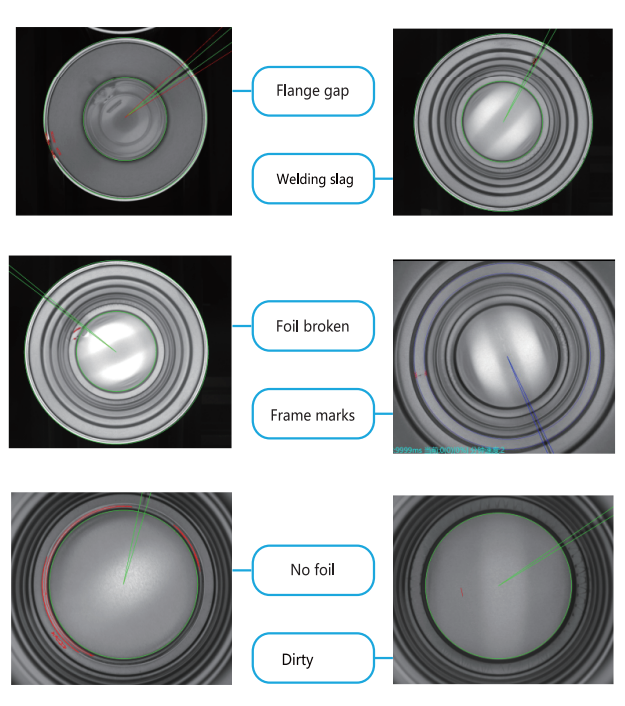

The Milk powder Cans inspection equipment is an automated quality inspection system for milk powder packaging, designed to maintain the highest standards of safety and hygiene. The system utilizes advanced image processing technology to thoroughly inspect the integrity of the cans from the inside out. This covers the flange, the internal can wall, and the bottom to separate contaminants or structural damage that could affect the quality of the milk powder before filling.

In terms of technical performance, this model supports a maximum inspection speed of 200 pieces per minute. The machine features a robust and durable structure with a total weight of approximately 130 kg and operates on low power at only 600W. The system accurately detects a wide range of defects, such as dirt, cracks, deformation, flange gaps, welding slag, ink contamination, hair, foil dents or breakage, and glue application issues at the bottom of the can.

Technical Highlights:

-

Inspection Speed: 200 pieces/min

-

Inspection Objects: Milk powder cans

-

Electrical System: AC 220V

-

Power: 600W

-

Air Pressure: 0.4~0.6Mpa

-

Machine Weight: Approximately 130 kg

-

Working Environment: 0~50°C (no condensation)

Drink cans Inspection Equipment

The Drink cans inspection equipment is a high-performance automated quality inspection solution for beverage packaging, designed to maintain the highest standards of cleanliness and safety on the production line. The system utilizes industrial camera technology to thoroughly detect foreign objects and structural abnormalities in cans, covering the flange, internal can wall, and bottom to ensure every container is perfect before entering the filling process.

In terms of technical performance, this model stands out with an inspection speed of up to 1,000 pieces per minute. The machine features a robust and compact structure with a weight of approximately 130 kg, operating under an AC 220V power system with a low power consumption of only 600W. The system provides comprehensive defect detection, including dirt, deformation, cracks, flange gaps, welding slag, ink contamination, hair, foil issues (dent/broken), and powder defects.

Technical Highlights:

-

Inspection Speed: 1,000 pieces/min

-

Inspection Objects: Drink cans

-

Detectable Defects: Dirt, deformation, cracks, foreign objects (e.g., hair), welding issues, and foil defects

-

Machine Weight: Approximately 130 kg

-

Electrical System: AC 220V, Power 600W

-

Air Pressure: 0.4~0.6Mpa

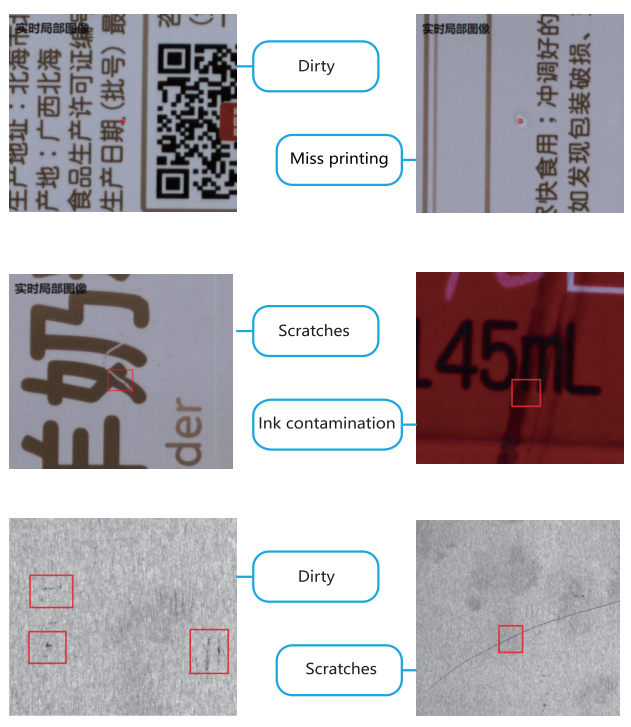

Tinplate printing Inspection Equipment

The Tinplate printing inspection equipment is a high-performance automated quality inspection system designed for printing on tinplate sheets. It is engineered to elevate quality control standards within the metal packaging manufacturing process. Utilizing advanced image processing technology, the system meticulously inspects the integrity of both the printing and the coating. It focuses on detecting defects that impact product aesthetics and standards, such as miss printing, ink contamination, scratches, text/pattern errors, different colors, and overprinting. Additionally, it inspects the coating face for dirt and various damages.

In terms of technical performance, this model supports an inspection speed of up to 120 meters per minute. The system is powered by 7.5kW under an industrial voltage of 380V AC. It is designed for high stability, featuring a large camera station and a clearly separated control cabinet. The equipment can operate continuously in factory environments with temperatures up to 50°C without condensation, enabling manufacturers to maintain consistent print quality and effectively reduce product rejection rates.

Technical Highlights:

-

Inspection Speed: $ge$ 120 meters/min

-

Inspection Objects: Printing on tinplate sheets

-

Detectable Defects: Miss printing, ink spots, scratches, text/pattern errors, color differences, overprinting, and dirt on the coating surface

-

Electrical System: AC 380V $pm$ 10%, Power 7.5kW

-

Air Pressure: $ge$ 0.6Mpa

-

Machine Dimensions: Control cabinet 1100 x 650 x 1600 mm / Camera station 3400 x 2015 x 1750 mm

Milk powder lid inspection equipment

The Milk powder lid inspection equipment is an automated quality inspection system for milk powder lids, emphasizing high precision and speed. The system is designed to control manufacturing standards to ensure maximum safety for the milk powder industry. It can comprehensively detect complex defects, covering the structural integrity of the lid (Curl)—such as gaps, deformation, and missing curls—as well as the integrity of glue application and the surface condition of both the foil and the printing.

In terms of technical performance, this model supports an inspection speed of up to 1,000 pieces per minute. It features advanced image processing technology capable of immediately rejecting substandard workpieces, such as dirty printing surfaces, print offsets, missing codes, and color contamination. The machine has a compact structure with a weight of approximately 130 kg and operates on low power at only 600W. It is designed for efficient integration into existing production lines to ensure that every package is perfectly sealed and meets the highest quality standards.

Technical Highlights:

-

Inspection Speed: 1,000 pieces/min

-

Inspection Objects: Milk powder lids

-

Detectable Defects: Lid deformation, missing glue (Miss glue), dirty surfaces, printing offsets/errors, and code errors

-

Machine Weight: Approximately 130 kg

-

Electrical System: AC 220V, Power 600W

-

Air Pressure: 0.4~0.6Mpa

-

Working Environment: 0–50°C (no condensation)

Double Seam Inspection Equipment

The Double Seam Inspection Equipment is a high-precision automated technology designed to verify the quality of can seams. It is specifically engineered to control the sealing standards of metal packaging within the food and beverage industries. Utilizing high-performance industrial cameras, the system provides a detailed, comprehensive inspection of the can’s seam edges to prevent leakage and contamination caused by incomplete sealing. It is capable of detecting a wide variety of critical structural defects, such as protrusions, depressions, false seams, and out-of-round packaging deformations.

In terms of technical performance, this model supports an inspection speed of up to 1,000 pieces per minute. The machine features a robust yet space-saving structure with a weight of approximately 130 kg. It operates under an AC 220V power system with a low power consumption of only 600W. The system is designed for stable operation in factory environments ranging from 0–50°C, equipped with precise image processing software that can immediately reject substandard workpieces. This ensures that every product is sealed securely and safely in accordance with international standards.

Technical Highlights:

-

Inspection Speed: 1,000 pieces/min

-

Inspection Objects: Double Seams

-

Detectable Defects: Protrusions, depressions, false seams, and out-of-round shapes

-

Machine Weight: Approximately 130 kg

-

Electrical System: AC 220V, Power 600W

-

Air Pressure: 0.4~0.6Mpa

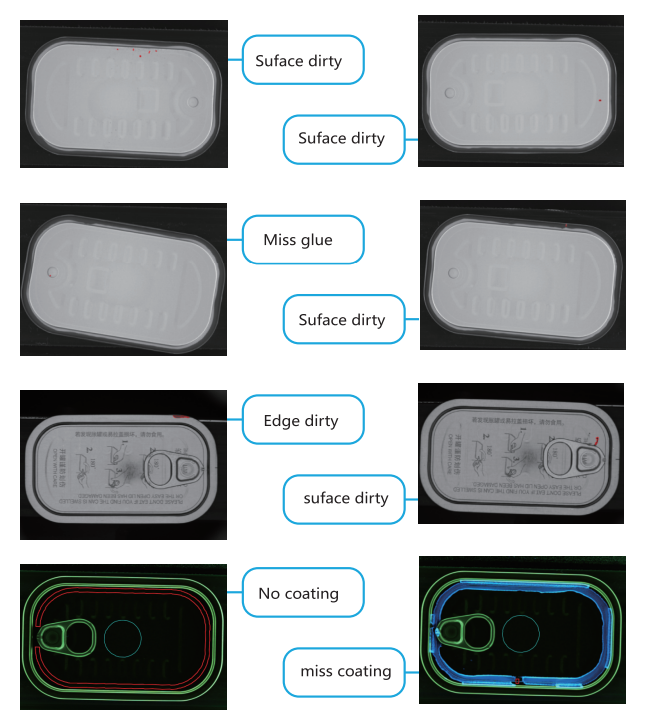

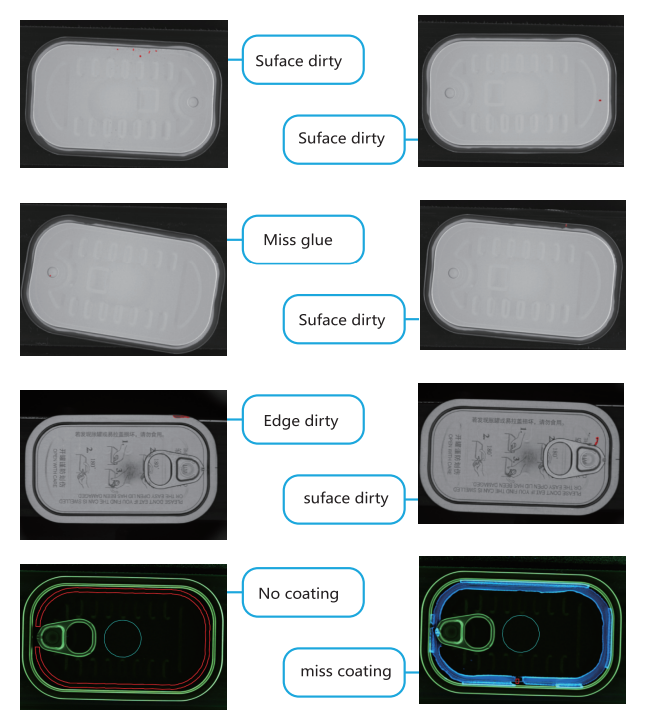

Special shape EOE inspection Equipment

The Special Shape EOE Inspection Equipment is an automated quality inspection system for easy-open ends with non-traditional shapes (such as oval or rectangular). It is specifically designed to handle the complexity of shapes that differ from standard circular lids. The system provides detailed detection across multiple critical areas: the Curl (identifying gaps, deformations, or missing curls), the integrity of Glue application, and the condition of the Surface/Ring to find smears, print offsets, or product mixing. Additionally, it inspects the Groove coating to prevent leakage and contamination.

In terms of technical performance, this model supports a maximum inspection speed of up to 850 pieces per minute. The machine features a compact structure weighing approximately 130 kg and is energy-efficient, consuming only 600W of power. The system is designed for stable operation under AC 220V and can perform continuously in industrial environments with temperatures ranging from 0–50°C. This ensures that every special-shaped lid meets international quality standards.

Technical Highlights:

-

Inspection Speed: 850 pieces/min

-

Inspection Objects: Special shape Easy-Open Ends (EOE)

-

Detectable Defects: Lid deformation, missing/intermittent glue, dirty surfaces, print offsets, and groove coating issues

-

Machine Weight: Approximately 130 kg

-

Electrical System: AC 220V, Power 600W

-

Air Pressure: 0.4~0.6Mpa

Special shape EOE inspection Equipment

The Special Shape EOE Inspection Equipment is an automated quality inspection system for easy-open ends with non-traditional shapes (such as oval or rectangular). It is specifically designed to handle the complexity of shapes that differ from standard circular lids. The system provides detailed detection across multiple critical areas, including the Curl (identifying gaps, deformations, or missing curls), the integrity of Glue application, and the condition of the Surface and Pull Ring to find smears, print offsets, or product mixing. Additionally, it inspects the Groove coating to prevent leakage and contamination.

In terms of technical performance, this model supports a maximum inspection speed of up to 850 pieces per minute. The machine features a compact structure weighing approximately 130 kg and is energy-efficient, consuming only 600W of power. The system is designed for stable operation under AC 220V and can perform continuously in industrial environments with temperatures ranging from 0–50°C. This ensures that every special-shaped lid meets international quality standards.

Technical Highlights:

-

Inspection Speed: 850 pieces/min

-

Inspection Objects: Special shape Easy-Open Ends (EOE)

-

Detectable Defects: Lid deformation, missing/intermittent glue, dirty surfaces, print offsets, and groove coating issues

-

Machine Weight: Approximately 130 kg

-

Electrical System: AC 220V, Power 600W

-

Air Pressure: 0.4~0.6Mpa

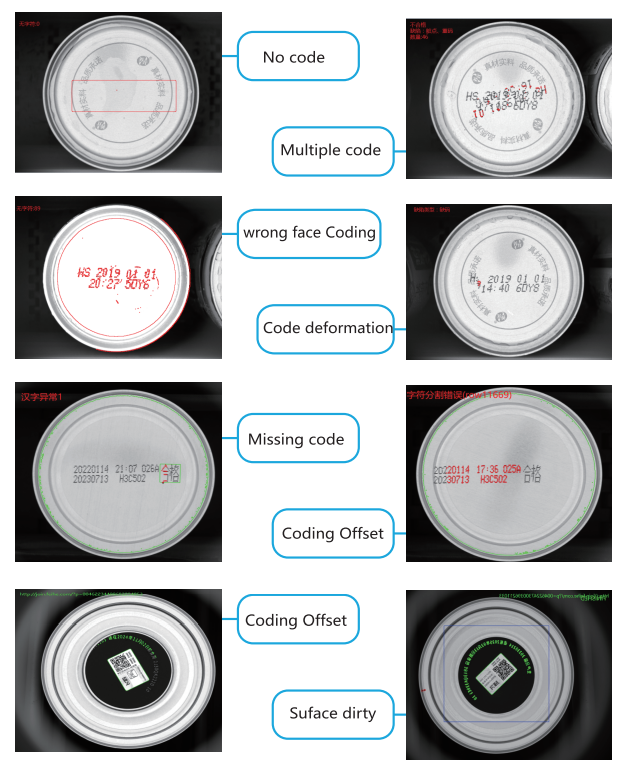

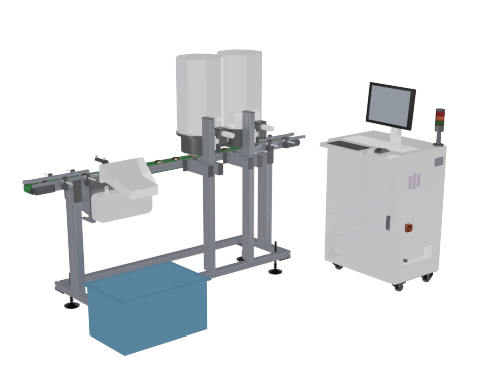

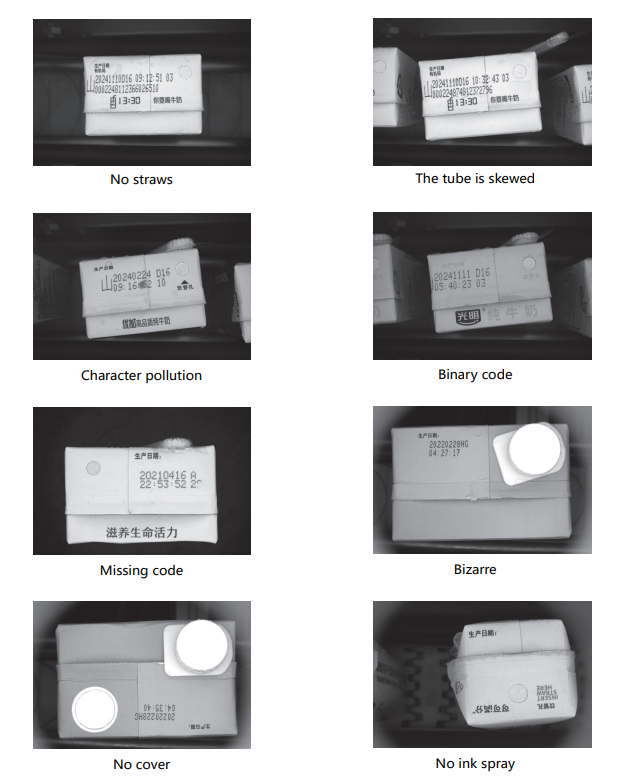

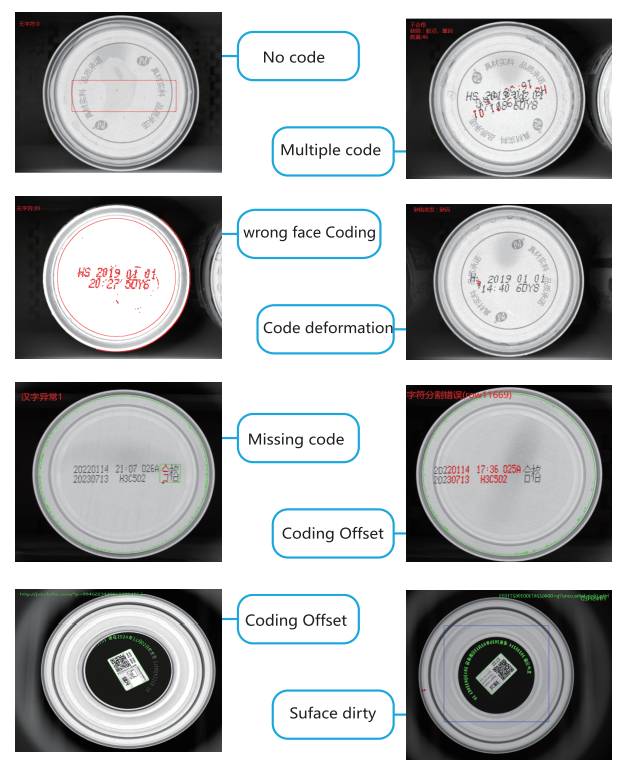

OCR Inspection Equipment

OCR Inspection Equipment is an intelligent Optical Character Recognition technology designed for high precision and speed. It is engineered to verify the accuracy of product codes (Coding) on various types of packaging. This system prevents discrepancies during the coding process, ensuring that critical information such as production dates, expiration dates, or lot numbers are correct and clearly legible before reaching the consumer. The system provides comprehensive defect detection, including missing codes (No code), coding offsets, error codes, missed codes (Miss code), multiple codes, wrong face coding, code deformation, and surface dirt.

In terms of technical performance, this model supports an inspection speed of up to 1,200 pieces per minute. It features a robust, durable, and compact structure with a weight of approximately 130 kg. Operating under an AC 220V power system with a low power consumption of only 600W, the system is designed for stable operation in industrial environments (0–50°C). It is equipped with advanced image processing software that can analyze and immediately reject workpieces with coding errors, enhancing brand reliability and professionalism.

Technical Highlights:

-

Inspection Speed: 1,200 pieces/min

-

Inspection Objects: Codes and text on packaging (OCR)

-

Detectable Defects: Missing codes, coding offsets, error codes, multiple codes, code deformation, and surface dirt

-

Machine Weight: Approximately 130 kg

-

Electrical System: AC 220V, Power 600W

-

Air Pressure: 0.4~0.6MPa

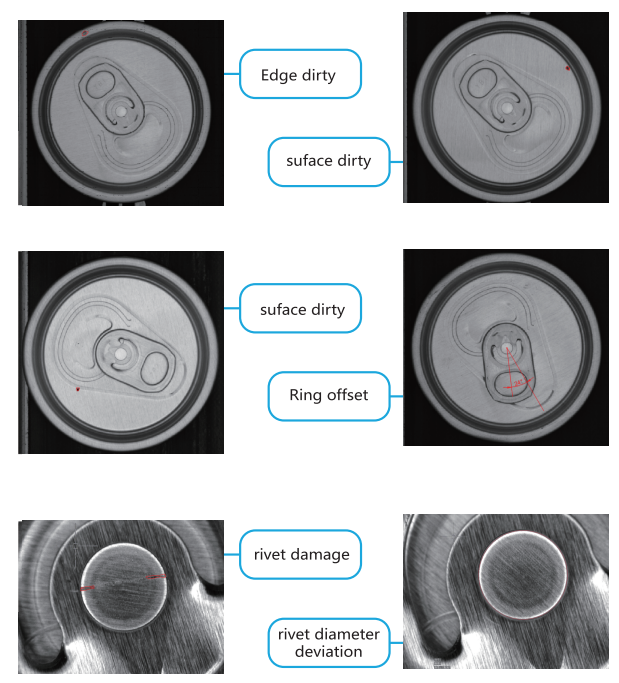

EOE Inspection Equipment

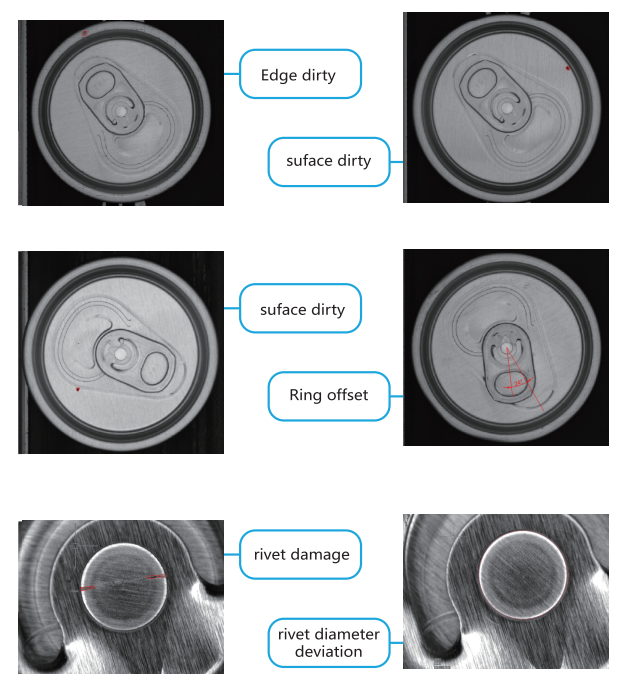

The EOE Inspection Equipment is an automated quality inspection system for Easy-Open Ends (EOE), focusing on maintaining high packaging integrity standards within high-speed production lines. The system utilizes precision industrial camera technology to inspect every critical component of the lid—from the edge structure and printed surface to the pull ring and rivet. This prevents defects that could compromise the seal or consumer safety. It provides comprehensive detection of defects, including edge deformation or dirt, surface dirt, pattern offsets, different colors, incorrect printing, ring offsets or damage, and rivet damage or diameter deviations.

In terms of technical performance, this model supports a maximum inspection speed of up to 1,000 pieces per minute. The machine features a compact and space-saving structure with a weight of approximately 130 kg. It operates under an AC 220V power system with a low power consumption of only 600W. Equipped with a stable image processing system, it performs efficiently and continuously in factory environments ranging from 0–50°C, helping factories maintain consistent production standards and fully reduce the need for manual inspection.

Technical Highlights:

-

Inspection Speed: 1,000 pieces/min

-

Inspection Objects: Easy-Open Ends (EOE)

-

Detectable Defects: Edge deformation, surface dirt, pattern offset, different colors, ring offset, and rivet damage

-

Machine Weight: Approximately 130 kg

-

Electrical System: AC 220V, Power 600W

-

Air Pressure: 0.4~0.6MPa

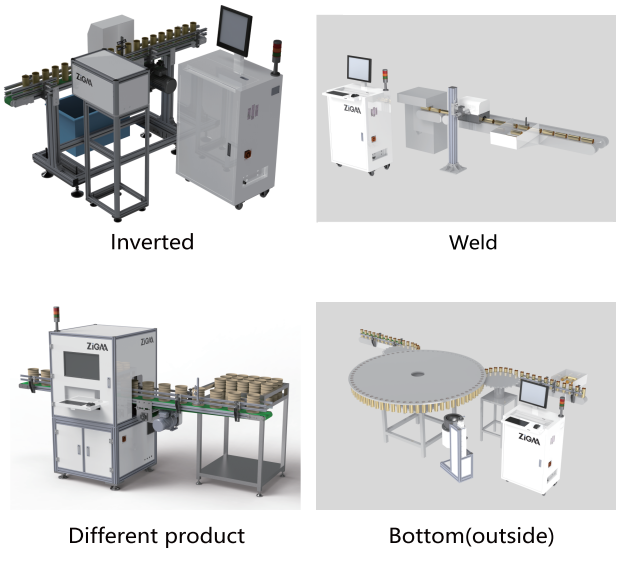

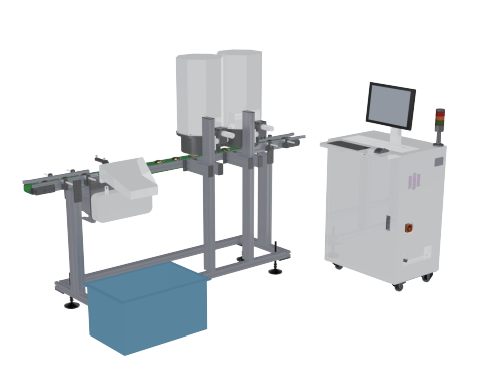

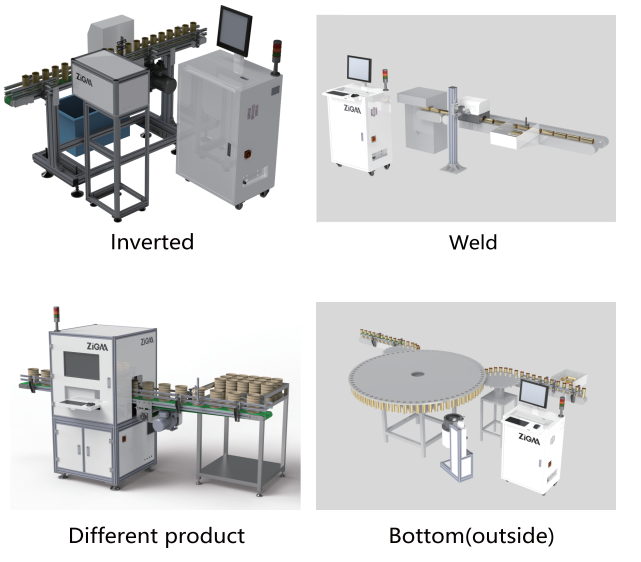

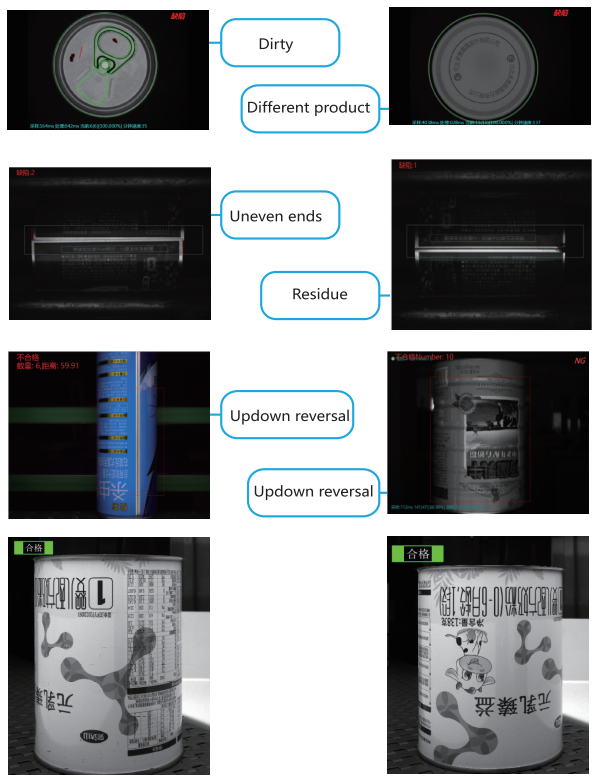

Weld / Inverted / Different product / Bottom (outside)

This inspection system is designed to simultaneously control quality at multiple critical points of the can. It emphasizes precision and high-speed operation, reaching up to 1,200 pieces per minute. This ensures that every product is perfect in terms of weld structure, correct positioning, and the removal of anomalies from the production line. The system consists of the following integrated sub-inspection units:

-

Weld Inspection System: Detects residues, weld tails, uneven ends, and wire blackening.

-

Inverted Inspection System: Checks for inside/outside reversal, printing reversal, irregular spacing (no spacing), and up-down reversal.

-

Different Product & Bottom (Outside) System: Sorts mixed products (different product) and inspects for up-down reversal as well as the integrity of the outer bottom of the can.

-

Other Detectable Defects: Identifies dirt and various residues on the product.

Technical Highlights:

-

Inspection Speed: 1,200 pieces/min

-

Inspection Objects: Welds, inverted cans, different products, and bottom (outside)

-

Electrical System: AC 220V

-

Power: 600W

-

Air Pressure: 0.4~0.6Mpa

-

Machine Weight: Approximately 130 kg

-

Working Environment: 0~50°C (no condensation)

สำนักงานใหญ่ :

107/69 หมู่ 6 ตําบลคูคต อําเภอลําลูกกา จังหวัดปทุมธานี 12130

อีเมล : [email protected]

โทรศัพท์: Office 02-1026862 Sales 086-7888414

Line : @unisyntech

Facebook : Unisyntech Packaging Solution.

ไทย

ไทย