1. Plastic Containers & Bottles Visual Inspection Machine

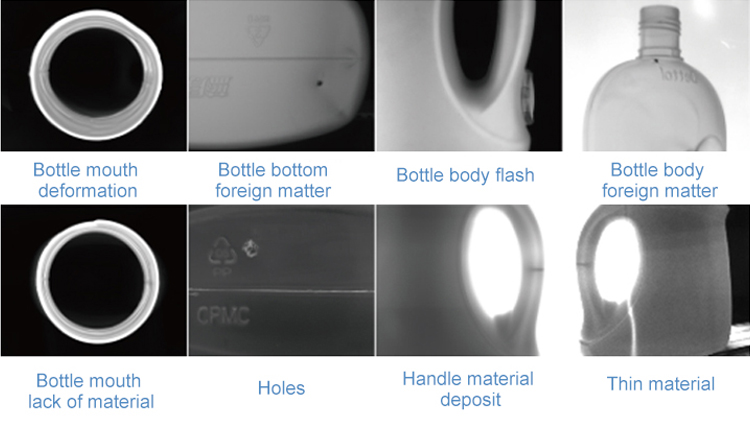

Plastic containers&bottles visual inspection equipment can detect beverage bottles, mineral water bottles, medical bottles, daily chemical bottles and other products, using 10 cameras to detect defects in the mouth, body and bottom of the bottle, such as black spots, dirt, material deposition, holes, flash and other defects.

Introduction:

Plastic bottle visual inspection equipment is an advanced automated equipment that combines machine vision technology, image processing technology and intelligent algorithms, and is specifically designed to detect various defects that may occur in the production process of plastic bottles. Plastic bottle visual inspection equipment is widely used in the plastic bottle production line of dairy products, beverages, daily chemicals, cosmetics, medicine and other industries. It can help enterprises improve product quality, reduce scrap rate, reduce production costs, and enhance market competitiveness.

Technical parameter

| Detective Defects | Black spot,dirt,material deposit,holes,flying edge… |

| Inspection Position | Bottle mouth,bottle neck,bottle body,bottle bottom,bottle handle |

| Inspection Speed | 0-600 bottles/min |

| Inspection Accuracy | 0.1mm |

| Machine Structure | Integral/spit machine |

Detect Defects

2. Plastic Caps&Closures Visual Inspection Machine

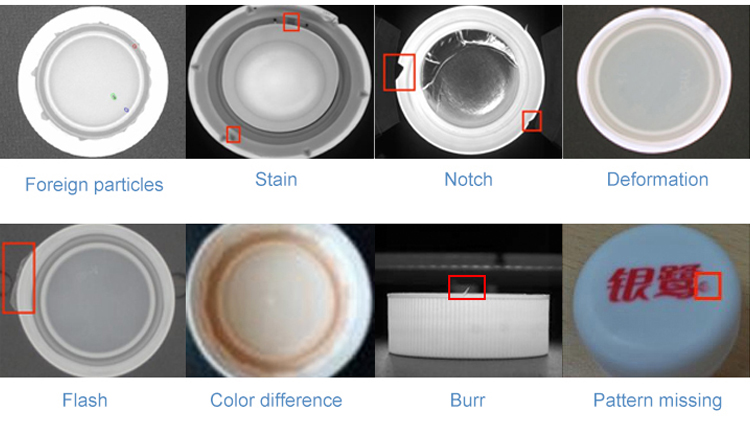

The plastic bottle cap visual inspection equipment uses 6 cameras to detect defects on the inner bottom of the cap, the inner side wall of the cap, the edge of the cap, and the outer bottom of the cap, such as damage, missing material, foreign matter, color difference and other defects.

Introduction:

The visual inspection machine for plastic bottle caps mainly uses high-performance industrial cameras instead of human eyes to take multi-directional and multi-angle photos of the inspected plastic bottle caps. The captured image information will be transmitted in real time to a dedicated image processing system, which converts the image signal into a digital signal based on pixel distribution, brightness, color and other information, and performs various operations to extract the characteristics of the target. By comparing with preset standards or templates, the system can identify flaws, defects or non-compliant parts on the bottle caps, and classify and remove them accordingly.

Technical parameter

| Detective Defects | Damaged,missing material,foreign matter,color difference… |

| Inspection Position | Inner caps,cap surface,cap&closures edge |

| Inspection Speed | 0-1000 caps/min |

| Inspection Accuracy | 0.5mm |

| Machine Structure | Integral/spit machine |

Detect Defects

3. Metal Containers&Bottles Visual Inspection Machine

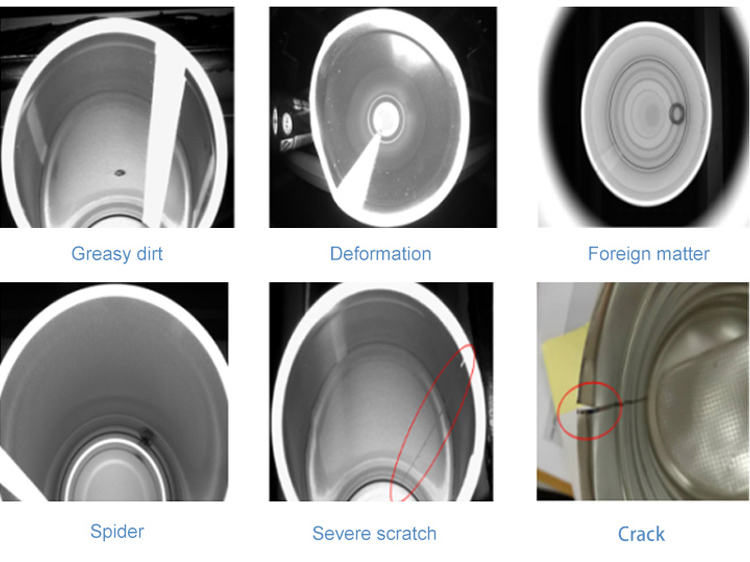

The metal containers&bottles visual inspection equipment uses 10 cameras to detect defects on the inner and outer surface, such as black spot, stain, hair, foreign particles, severe cracks and other defects.

Introduction:

Metal containers&bottles quality inspection machine, the main function is to comprehensively detect impurities, defects and other problems in metal containers&bottles through optical sensors and camera systems.

Wonderful Tech’s products have the characteristics of high quality, high performance and high reliability, which can meet the needs of different industries for metal container quality inspection. When choosing, you can choose or customize the appropriate inspection equipment according to your own needs and budget.

Technical parameter

| Detective Defects | Black spot,stain,hair,foreign matter,crack,deformation,damaged… |

| Inspection Position | Can mouth,can inner wall,can outer wall,can bottom |

| Inspection Speed | 0-1000 cans/min |

| Inspection Accuracy | 0.5mm |

| Machine Structure | Integral/spit machine |

Detect Defects

4. Metal Caps&Closures Visual Inspection Machine

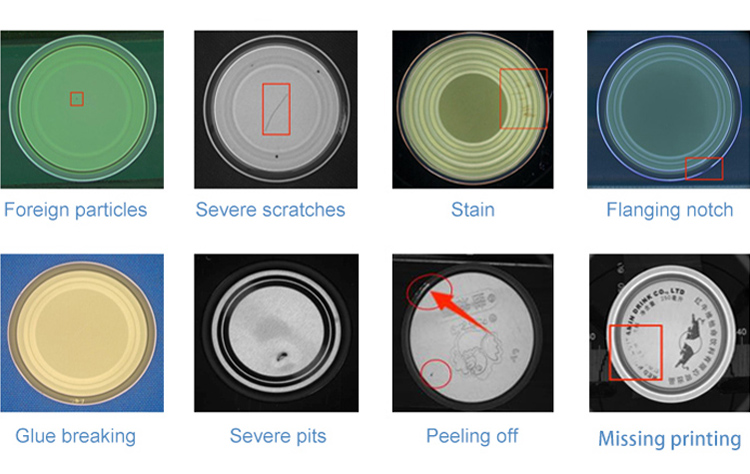

The metal caps&closures visual inspection equipment uses 2 cameras to detect defects on the glue injection surface and non-glue injection surface, such as damaged, dirt, severe scratches, severe cracks, deformation and other defects.

Introduction:

The metal caps&closures quality inspection machine is usually based on machine vision technology. It is a fully automatic inspection equipment specially used to detect the quality of metal caps&closures, such as twist-off closures, aluminum caps, tinplate caps.

At the same time, it is also an indispensable detection equipment in modern industrial production. Its advanced machine vision technology and the convenience of automated operation provide a strong guarantee for the improvement of product quality.

Technical parameter

| Detective Defects | Damaged,dirt,scrach,crack,deformation… |

| Inspection Position | Caps&closures edge,surface |

| Inspection Speed | 0-2000 cans/min |

| Inspection Accuracy | 0.5mm |

| Machine Structure | Integral/spit machine |

Detect Defects

5. Printing Tinplate Visual Inspection Machine

Printing tinplate visual inspection machine uses 2 cameras to detect defects on the Printing surface and coated surface, such as severe scratches, ink dye, stain, foreign particles and other defects.

Introduction:

Printing tinplate visual inspection machine uses a high-precision camera to capture images of tinplate prints, and then transmits these images to a high-performance computer processing system. The computer uses advanced image processing algorithms to perform image preprocessing, feature extraction, defect detection, classification and identification, etc., and ultimately realizes automated detection of surface defects in printing tinplate.

Technical parameter

| Equipment Classification | On-line detection of large sheet iron | On-line detection of multi sheet iron |

| Detective Defects | Black spots,scratches,stain,print burr… | Scratches,black spots,dirt,foreign matter… |

| Inspection Position | Printing surface | Printing surface and coated surface |

| Inspection Speed | 120pcs/min | Synchronization with production line |

| Inspection Accuracy | 0.1mm | 0.1mm |

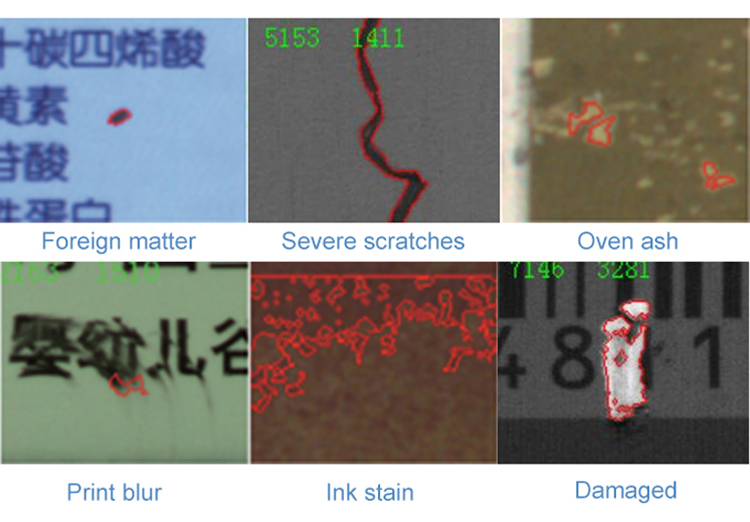

Detect Defects

Main features:

① Efficiency: Visual inspection equipment can achieve high-speed and continuous online inspection, greatly improving inspection efficiency.

② Accuracy: Using machine vision technology, visual inspection equipment can achieve detailed inspection of printing surface and coated surface, and the recognition accuracy is much higher than manual inspection, reducing the possibility of missed inspection and false inspection.

③ Stability: Visual inspection equipment can work 24 hours a day, with stable and reliable performance, fully meeting the needs of large-scale production.

④ Intelligence: Advanced visual inspection equipment is also equipped with an AI deep learning system, which can continuously learn and optimize the inspection model to improve inspection accuracy.

Head Office :

107/69 Moo 6, Khu Khot, Lam Luk Ka District, Pathum Thani 12130

E-mail : [email protected]

Mobile: Office 02-1026862 Sales 086-7888414

Line : @unisyntech

Facebook : Unisyntech Packaging Solution.

ไทย

ไทย