Auxiliary Equipment

As a system supplier Shanghai RUIYUAN printing equipment Co., Ltd provides all the auxiliary equipment necessary to ensure smooth highly automated production and offers individually tailored solutions for process optimization and automation.

Stacker

To achieve non-stop production, one box is used for collecting unqualified products, the other two boxes receive the sheet change-over freely.

Read more

Pile turner

Our pile turners are mainly for metal printing and coating. The working platform is plate type or drum type, easy for loading and unloading stackers. They can handle metal sheets up to a maximum size of 1143(mm)×965(mm) and stack weights up to 3,600 kg, and suitable for all typical applications in the industry.

Read moreCTP (Computer To Plate)

CTP (Computer To Plate) refers To Computer direct Plate making, which uses laser scanning To record digital page information on the Plate, and then obtains the Plate through appropriate post-processing.

Read more

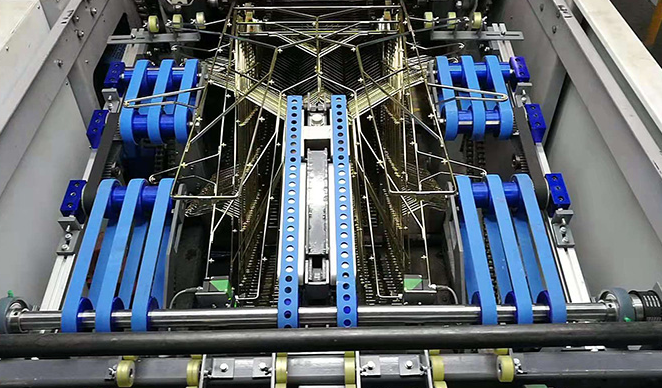

Wickets for Ovens

We can also provide various sizes and specifications of wickets with chrome plating, nickel plating, chrome plating, and zinc plating as surface treatment. TIG welding, riveting, or spot welding can be used.

Read moreMetal Printing and Coating Online Production Line Monitoring

The online monitoring technology is suitable for metal printing and coating production line, which greatly improves the yield and reduce metal sheets waste.

Read more

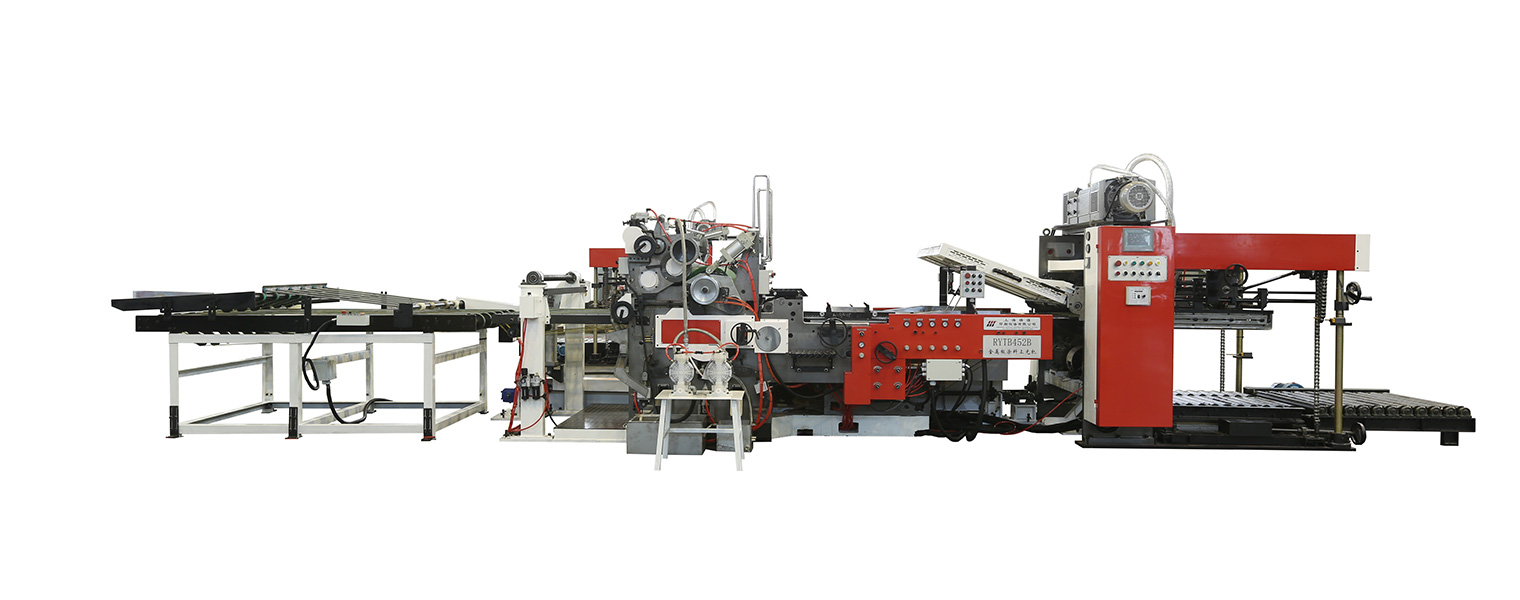

Offset Printing Machine New Function

1. Intelligent Control & Digital Setup

-

Digital sheet-change system by one button: Allows for instantaneous adjustment of machine settings for different sheet sizes, significantly reducing change-over downtime.

-

Automatic Offset Plate Change Over: Automates the replacement of printing plates, increasing speed and reducing manual labor.

-

Automatic plate cylinder position adjustment: Ensures high-precision printing by automatically aligning the plate cylinders to the correct position.

2. Advanced Ink & Dampening Systems

-

INKPRO Ink fountain remote control system: Enables operators to precisely adjust ink levels and flow directly from the remote control console.

-

Auto ink mixing device: Keeps ink consistency and viscosity uniform throughout the production run to ensure color stability.

-

Temperature control of the ink delivery system: Regulates the heat within the inking system to prevent printing defects caused by temperature fluctuations.

-

Centralized control of dampening water system: Manages the water-to-ink balance from a central unit for optimal print quality.

3. Quality Assurance & Automated Maintenance

-

Automatic blanket scrubbing device: Automatically cleans the printing blankets, reducing the need for manual intervention and machine stops.

-

Test sheet management system: Streamlines the process of checking and managing trial sheets before full-scale production.

-

Online monitoring: A real-time surveillance system that detects defects instantly, ensuring a high yield and minimal waste.

4. Material Handling & Alarm Systems

-

Automatic VAC Stack: A vacuum-assisted stacking system that neatly organizes finished metal sheets without damaging the printed surface.

-

Deviation alarm: An intelligent alert system that notifies operators immediately if any part of the production line deviates from set parameters.

-

Automatic feeder of pallets: Automates the feeding of pallets into the line, supporting continuous “non-stop” production.

สำนักงานใหญ่ :

107/69 หมู่ 6 ตําบลคูคต อําเภอลําลูกกา จังหวัดปทุมธานี 12130

อีเมล : [email protected]

โทรศัพท์: Office 02-1026862 Sales 086-7888414

Line : @unisyntech

Facebook : Unisyntech Packaging Solution.

ไทย

ไทย