Guangzhou Dosion Technology Co., Ltd. is a comprehensive testing solutions provider. We specialize in the design and installation of In-line Testing Equipment for industries requiring the highest levels of precision. Our expertise serves the following sectors such as Food and Beverage, Beer and Water, Condiments, Pharmaceuticals , Packaging

Our Commitment to Excellence

We are dedicated to delivering testing equipment that is both efficient and highly accurate. Our team does more than just sell machinery; we provide “Tailored Solutions” customized to the specific needs and characteristics of our clients’ products. By integrating our technology with your production line’s unique requirements, we ensure seamless quality control.

Advanced Technology & Global Standards

We combine cutting-edge technologies—including Acoustic, Laser, and X-ray systems—with intelligent software algorithms to achieve a detection accuracy of 99.99% at high production speeds. Our proprietary solutions meet the rigorous requirements of international brands. We are ready to be your partner in driving sustainable business growth through world-class inspection standards

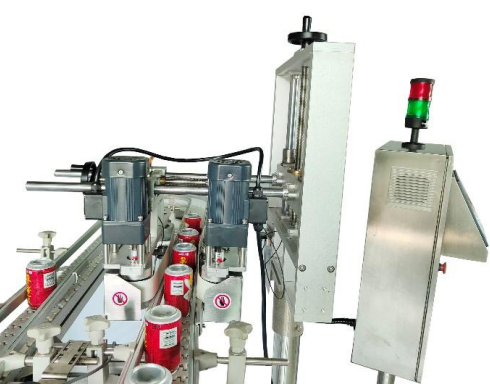

Vacuum/Pressure Testing Equipment (Acoustic Technology)

Innovative Sound-Based Quality Inspection for Maximum Precision This system is built on world-leading acoustic technology principles. Utilizing the Fourier algorithm, the probe applies a “non-contact” tapping action to the container’s top as it passes through the detection zone, triggering specific acoustic patterns. Because containers with different vacuum levels emit distinct sounds, this advanced technology can accurately identify leaks through sound analysis and provide continuous monitoring.

Product Highlights

-

Advanced Acoustic Analysis: Utilizes proprietary algorithms and high-precision digital signal processing to detect leaks via sound with high accuracy.

-

Maximum Accuracy: Ensures quality with a measurement accuracy of 99.99%.

-

High-Speed Processing: Capable of detecting up to 1,200 cans per minute (speed varies by container and conveyor).

-

Intelligent Control System: Features an 8-inch smart color touch screen for easy operation.

-

Multilingual Interface: Supports both Chinese and English menus (switchable for export equipment).

-

Smart Memory: Includes a function to store up to 20 different product formulas.

-

Industrial Durability: The control box is built to IP65 class standards, providing excellent protection against dust and water.

Vacuum/Pressure Testing Equipment (Proximity Technology)

Precision Detection of Container Lids via Magnetic Field Technology This system is specifically designed to measure pressure or vacuum levels in food cans, beverage containers, glass jars, and snap-on bottle lids by detecting the deflection of closures. The proximity sensor generates a continuous magnetic field to monitor the distance between the closure and the metal lid, producing proportional curvature data that converts into a digital proximity signal. This process generates numerical values reflecting the closure’s dimensional integrity. When product quality metrics exceed specified process parameters, the system automatically rejects the items.

Key Highlights

-

Maximum Inspection Speed: Supports production capacities of up to 1,500 cans per minute, making it the fastest in its category.

-

High-Precision Measurement: Utilizes high-precision digital signal processing (DSP) to analyze the integrity of the lid’s shape.

-

Automatic Rejection System: Immediately removes products from the production line when quality standards are not met.

-

User-Friendly Interface: Controlled via an 8-inch smart color touch screen equipped with an intelligent fault diagnosis system.

-

High Durability: The control box meets IP65 standards, providing excellent protection against water and dust for industrial environments

Vacuum/Pressure Testing Equipment (Laser Technology)

High-Precision Laser Technology for Versatile Packaging Inspection This quality inspection system utilizes laser technology to perform detailed measurements of pressure or vacuum levels. The laser sensor continuously scans the surface of the container lid to detect deflection (bulging or concave movement). The system analyzes the collected surface data and compares it against the customer’s specific process requirements. If a product’s quality value exceeds these requirements, the system automatically rejects it immediately.

Key Highlights

-

High Precision and Resolution: Uses laser beams to analyze lid surfaces for maximum accuracy of 99.99%.

-

Versatile Packaging Support: Suitable for a wide range of containers, including food cans, beverage cans, glass jars, and plastic bottles.

-

Efficient Processing: Capable of rapid inspection at speeds up to 1,200 cans per minute (depending on container and conveyor).

-

High-Precision Digital Signal Processing: Ensures reliable data analysis for every item on the line.

-

User-Friendly Interface: Features an 8-inch smart color touch screen with multilingual menus, supporting both Chinese and English for export equipment.

-

Industrial Standard Build: Equipped with a control box rated at IP65 for dust and water protection, along with an intelligent screen fault diagnosis system

Inline Canned Food Vacuum Detector

Intelligent Solutions for Inspecting Special-Shaped Metal Packaging This system elevates quality control by transitioning from manual labor to high-precision automation. It is designed for rapid vacuum monitoring on food production lines and supports all types of metal-lid sealed containers. It is specifically effective for unique shapes such as oval cans, square cans, and horseshoe-shaped cans.

Key Highlights and Technology

-

Non-contact Inline Detection: Combines acoustic and scanning technologies using ultrasonic and electromagnetic wave sensors to inspect quality without touching the product.

-

Comprehensive Inspection Functions: Measures critical parameters including leakage detection, vacuum status, double or missing lids, and can expansion.

-

Compatible with Easy-Open Lids: The system is engineered to perform accurately without being affected by easy-open pull tabs.

-

Automatic Rejection: Automatically eliminates nonconforming products that exceed preset system thresholds.

-

Accuracy and Stability: Features a high removal capacity for unqualified containers at a rate of ≥99.99%

Whole Box Vacuum Inspection Machine

Innovation in Through-Box Quality Inspection for Maximum Screening Efficiency Elevate your quality control to the next level with a continuous vacuum inspection system for products already packed in cartons or shrink-wrapped film. Utilizing ultrasonic waves and high-energy electromagnetic waves, this technology features excellent penetration through cardboard boxes or shrink film. It monitors the vacuum level of every container inside the box simultaneously in real-time without needing to open the packaging.

Inspection Capabilities

-

Vacuum Level Monitoring: Accurately measures the vacuum degree of metal-lid containers.

-

Container Defect Detection: Identifies leaks, expansion, empty contents, double covers, and missing covers.

-

Internal Box Integrity Check: Detects reversed cans, missing cans, and broken containers within the box.

-

Automatic Rejection System: Boxes exceeding preset threshold parameters are automatically removed from the inspection process.

Product Highlights

-

Non-contact Inline Detection: Operates continuously on the production line without physical contact with the carton.

-

Versatile Packaging Support: Suitable for various can packaging configurations, including 2×3, 3×4, 4×6 , and 6×6 layouts.

-

Adjustable Probes: Can be equipped with up to 4 probes, determined by the number of columns in the packaging box.

-

Intelligent Control Interface: Features a color touch screen operating system supporting both English and Chinese languages.

Vacuum/Pressure Testing Equipment (Laser Technology)

High-Precision Laser Technology for Versatile Packaging Inspection This quality inspection system utilizes laser technology to perform detailed measurements of pressure or vacuum levels. The laser sensor continuously scans the surface of the container lid to detect deflection (bulging or concave movement). The system analyzes the collected surface data and compares it against the customer’s specific process requirements. If a product’s quality value exceeds these requirements, the system automatically rejects it immediately.

Key Highlights

-

High Precision and Resolution: Uses laser beams to analyze lid surfaces for maximum accuracy of 99.99%.

-

Versatile Packaging Support: Suitable for a wide range of containers, including food cans, beverage cans, glass jars, and plastic bottles.

-

Efficient Processing: Capable of rapid inspection at speeds up to 1,200 cans per minute (depending on container and conveyor).

-

High-Precision Digital Signal Processing: Ensures reliable data analysis for every item on the line.

-

User-Friendly Interface: Features an 8-inch smart color touch screen with multilingual menus, supporting both Chinese and English for export equipment.

-

Industrial Standard Build: Equipped with a control box rated at IP65 for dust and water protection, along with an intelligent screen fault diagnosis system

Leak Detection (FC-800 Series)

Squeezer Compression Technology for Precise Internal Pressure Monitoring During the production of PET bottle gas-filled products, aluminum foil-sealed plastic bottles, and 2-piece or 3-piece cans, factors such as equipment stability and packaging fluctuations can lead to product leakage. To address these challenges, Dosion has developed and launched a squeezer pressure detection machine. Utilizing belt compression detection technology combined with high-precision side sensors, this device sensitively monitors the internal pressure of containers.

Intelligent Operation Mechanism

-

Processing Technology: The system converts perceived digital signals from the compression process to identify the true internal pressure of the product.

-

Automatic Rejection: The system identifies and eliminates products with pressure defects from the production line immediately if they do not meet process requirements.

-

Precise Inspection: Utilizing DSP (Digital Signal Processing) technology, the controller analyzes measurements and assigns a “Quality Score” to every container.

Force Measurement (FC-800F)

Suitable for: Detection of leakage and over-pressure in nitrogen-filled beverages and carbonated products.

-

Operating Principle: Parallel conveyor belts carry containers through a load sensor that squeezes the sidewalls to measure tightness and analyze internal pressure.

-

Processing System: Utilizes DSP (Digital Signal Processing) technology to analyze measured values and assign a quality score to each individual unit. If the pressure does not meet standards, the system triggers an automatic rejection.

-

Key Highlights: Provides rapid, highly accurate, and continuous monitoring within the production line

Physical Defects Inspection (FC-800L & FC-800P)

Suitable for: Checking the integrity of closures and assessing pressure or vacuum levels in food cans, beverage containers, glass jars, and snap-on bottle caps.

-

Detection Functions: The system identifies abnormalities such as caps that are too high, warped, or missing entirely.

-

Operating Principle: Sensors continuously monitor the surfaces of metal lids to measure deflection. This measurement is used to evaluate the internal pressure or vacuum levels.

-

Key Highlights: The system calculates quality metrics based on sampled data related to lid profiles. These values are compared against user-defined thresholds, triggering the automatic rejection of any product that exceeds standards

Compression Test (FC-800C)

Suitable for: Leakage detection in plastic containers and canned beverages.

-

Operating Principle: Containers pass through a dual parallel conveyor system where the belts apply external force to the sidewalls, effectively compressing the top space.

-

Inspection System: Load sensors measure the internal pressure of the container just before it leaves the detection equipment.

-

Processing: The controller utilizes DSP technology to analyze these measurements and assign a specific quality score to each container.

-

Automatic Rejection: If the quality value exceeds the preset threshold, the container is automatically removed from the production line.

Physical Defects Inspection (Technical Specifications)

-

Functionality: Performs pressure detection, leakage detection, and identifies missing caps.

-

Operating Speed: Operates at a maximum speed of 1,000 bottles per minute.

-

Detection Accuracy: Maintains an accuracy level of ±2 PSI.

-

Applicable Containers: Compatible with PET bottles, two-piece cans, standard cans, plastic bottles, soft packaging, and aluminum foil.

-

Control Interface: Equipped with a color touch screen interface.

-

Machine Dimensions: The equipment size is 800 times 1,000 times 1,700 mm.

-

Power Supply: Requires AC220V, 50Hz.

-

Power Consumption: Total power consumption is 300W.

-

Air Source Requirements: Operates with a compressed air source of 5–8 Bar.

-

Structural Material: Built with a stainless steel chassis providing industrial protection up to IP65 level.

.

Food X-Ray Inspection Machine

Intelligent Contaminant Detection Technology for Maximum Product Safety This inspection system utilizes X-rays to irradiate products and obtain transmission images. Advanced image processing technology is then used to identify whether the product contains foreign matter such as stainless steel, iron, ceramics, glass, stones, bones, hard rubber, and hard plastic.

Key Highlights

-

Intelligent Processing System: Developed based on the SAET Insight algorithm platform, featuring high sensitivity and stability.

-

Automatic Self-Learning: The system can automatically learn product characteristics using only 5–10 foreign-body-free samples, allowing complex products to be configured easily without technician intervention.

-

Operating System Stability: Utilizes a server-grade Windows operating system to ensure stable operation and virus immunity.

-

Practical Design: The conveyor belt can be quickly removed in just 5 seconds for convenient on-site cleaning and replacement.

-

Industrial Durability: Built with 304 stainless steel and features an IP65 protection rating.

-

User Safety: X-ray leakage is less than 1uSv/h, meeting relevant safety standards and including safety monitoring capabilities.

Food X-Ray Inspection Machine

Intelligent Detection Technology for Maximum Product Safety This system uses X-rays to irradiate products to obtain transmission images, utilizing advanced image processing technology to identify foreign matter. It can detect a wide variety of contaminants, including stainless steel, iron, ceramics, glass, stones, bones, hard rubber, and hard plastic.

Key Characteristics and Performance

-

Intelligent Algorithm: Developed on the SAET Insight algorithm platform, it offers high sensitivity and stability.

-

Self-Learning System: Complex products can be configured through an automated learning process that requires only 5–10 foreign-body-free samples for training.

-

Global Standard Operating System: Utilizes a server-grade Windows operating system to ensure maximum stability and virus immunity.

-

Durable Design: Features a fully sealed design to withstand humid environments and a double-layer heat cycle for high temperatures.

-

Anti-Condensation: Includes an anti-condensation design to handle temperature fluctuations.

-

High Safety Standards: External X-ray leakage is less than $1mu Sv/h$, meeting relevant safety standards and including safety monitoring.

User-Friendliness

-

Easy Cleaning: The equipment’s inspection channel has an IP66 protection rating and is washable.

-

Quick Maintenance: The belt can be removed in just 5 seconds, making on-site cleaning and replacement extremely convenient.

-

Data Management: Product configurations and inspection images are automatically saved and can be exported for analysis.

-

Modular Design: The modular architecture eliminates the need to purchase a new main unit for future production line upgrades.

ไทย

ไทย