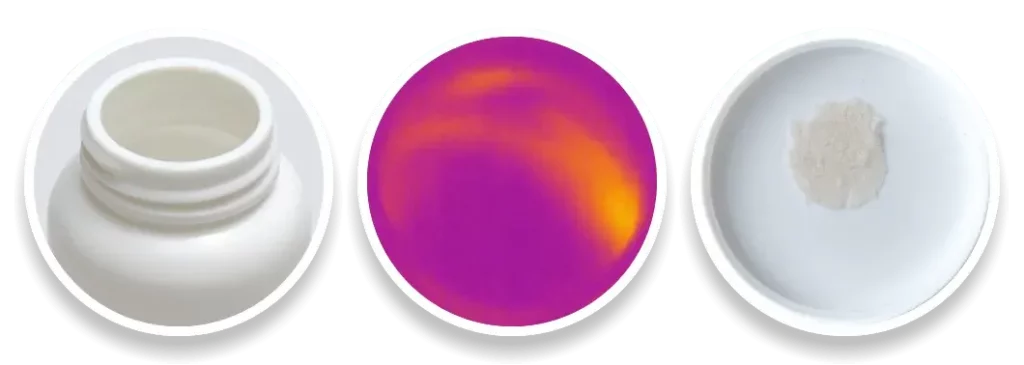

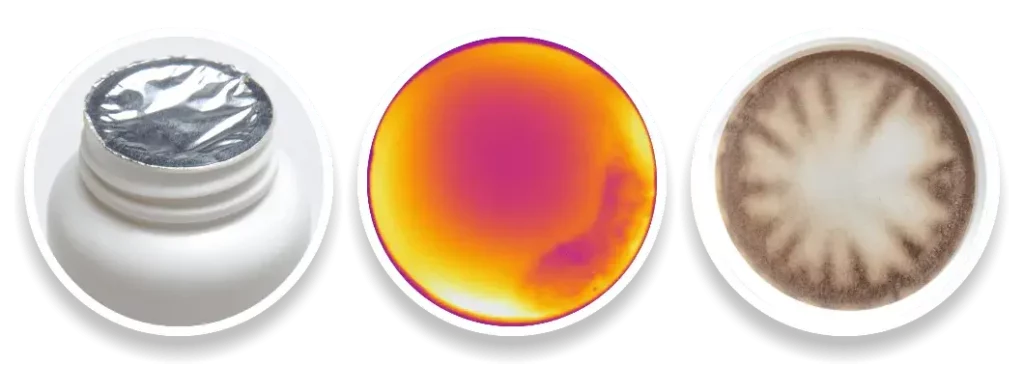

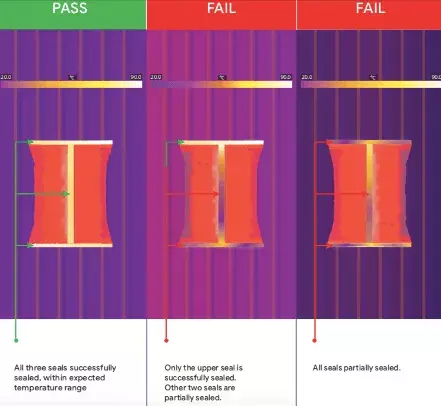

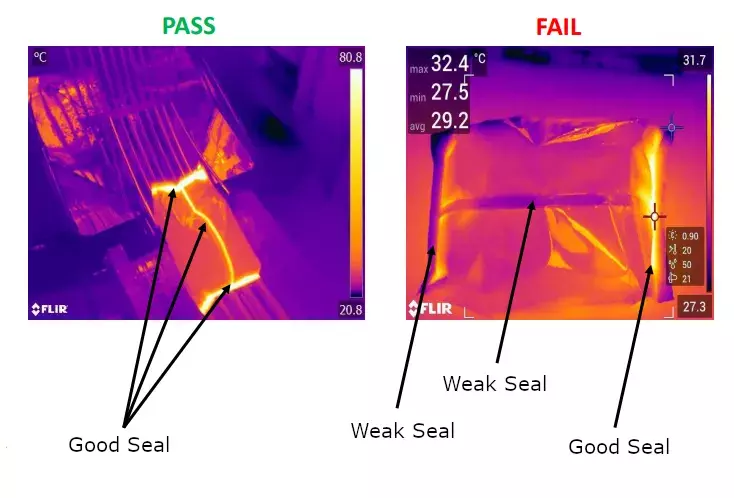

Spookfish Innovations solve complex manufacturing challenges using cutting-edge computer vision and machine learning techniques. Snipe is an online heat seal inspection system that retrofits onto existing packaging lines. Poor induction seal quality remains a serious concern in the FMCG industry. Sub-standard seals can compromise product integrity, lead to spillages later in the production process and even cause major public health risks. Using the latest in high resolution thermal technology, Snipe accurately detects any areas of potential leakage or damage to a seal, verifying the integrity of the packaging and rejecting any defective products.

ไทย

ไทย