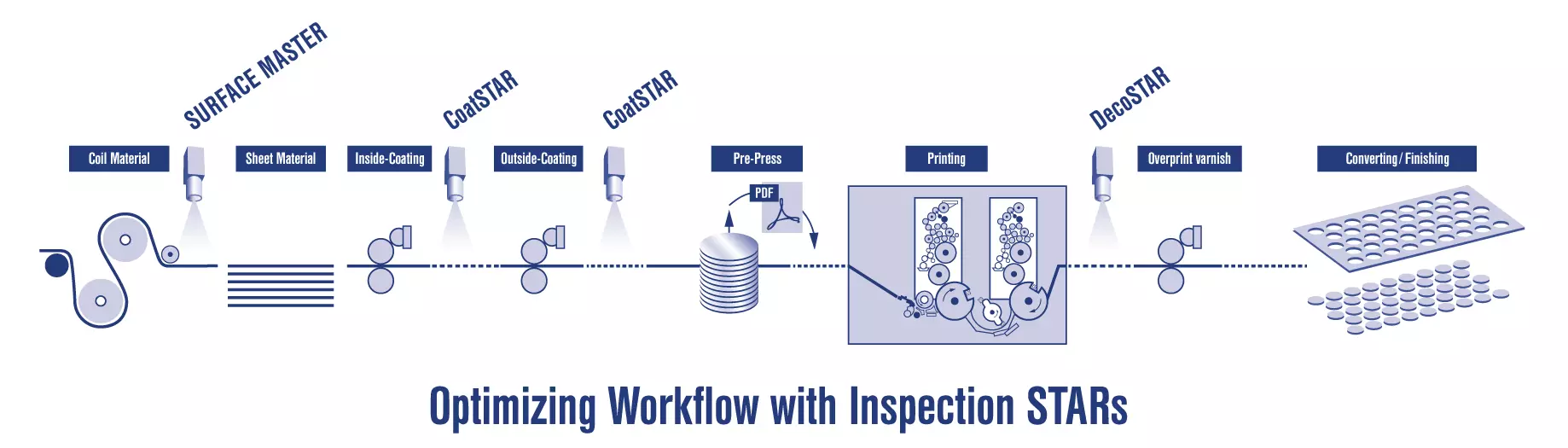

Metal sheet decoration is a complex process that places high demands on printing, coating, and material integrity. A whole range of defect sources, such as color deviations, printing defects, contaminations, edge defects, and material defects, can significantly impair the quality of the final product. One of the biggest challenges, however, is to achieve high product quality at a fast production speed.

Our inline printing and coating inspection solutions ensure both 100% quality control and process optimization at maximum throughput.

DecoStar

Reliable quality control for metal printing on steel and aluminum sheets is guaranteed by the DecoStar inline print inspection solution. The flexible system can be used for tinplate or aluminum as well as high-gloss or matte motifs on any type of machine. With highly efficient LED lighting, the system reliably identifies color deviations as well as edge and material defects. In addition, featuring an intuitive multi-touch user interface, the system delivers high-quality defect data that helps eliminate serial defects and reduce waste.

Typical defects

- Scratches

- Hickeys

- Splashes

- Streaks

- Register defects

- Missing print

- Color deviations

- Print on areas, which should be empty

- Ghosting

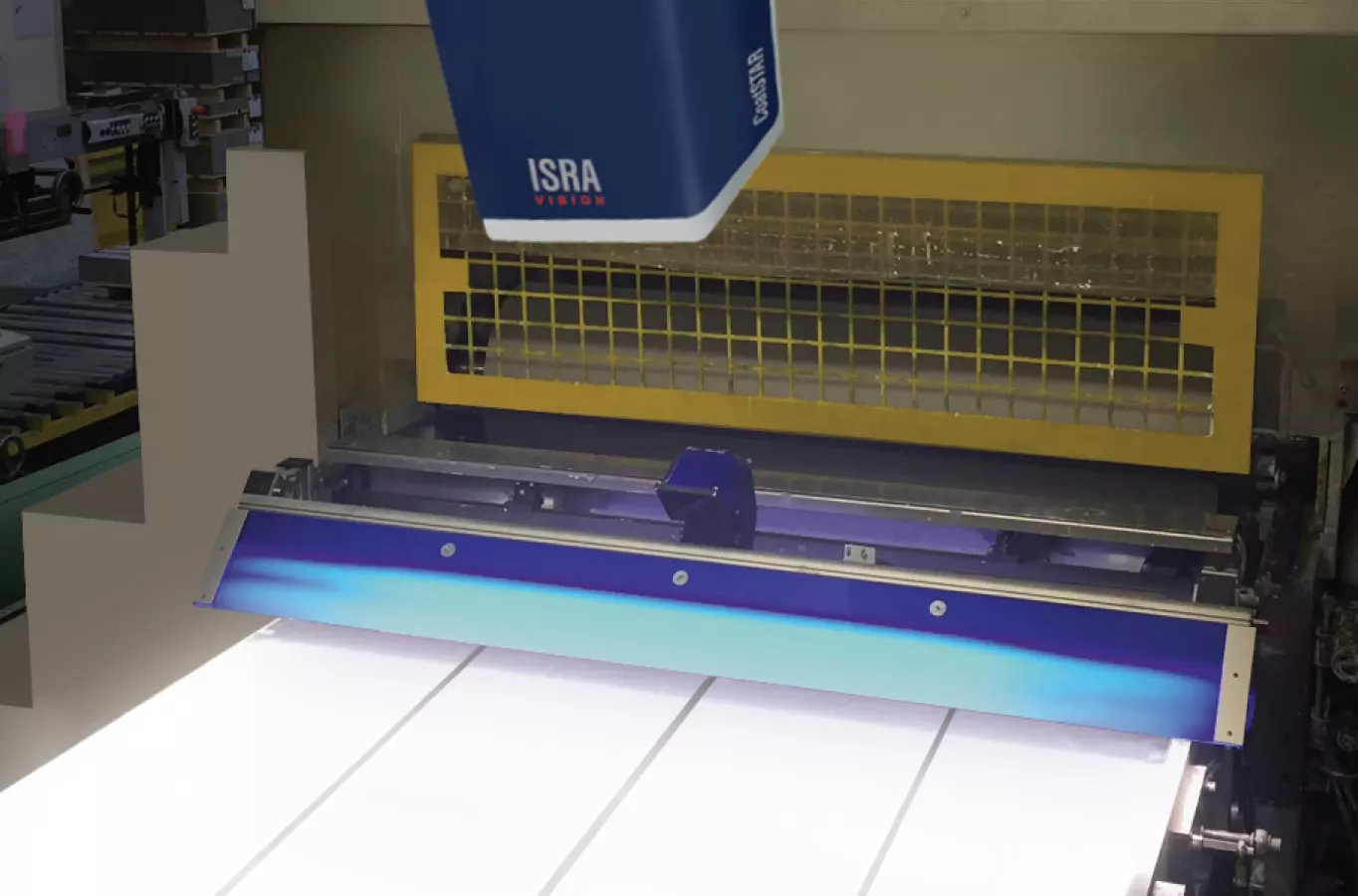

CoatStar

ISRA PARSYTEC provides solutions for the full range of surface inspection tasks for continuous strip products with a unique and most complete product portfolio. Our goal is to provide advanced solutions along the entire steel production chain. Hundreds of successfully installed systems confirm the benefit of many years of experience and technological competence. Whether it be casting, hot or cold rolling, pickling, annealing, galvanizing, coating or the finishing process – all are covered, as well as end products such as rails.

Typical defects

- Scratches

- Missing coating

- Coating splashes in welding areas

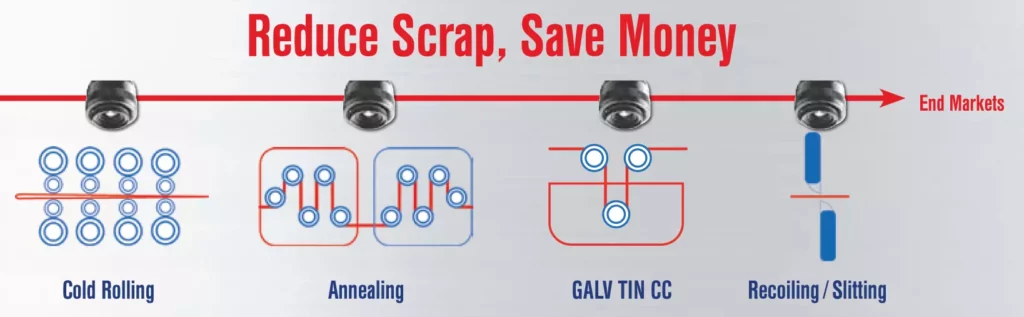

PARSYTEC

ISRA PARSYTEC provides solutions for the full range of surface inspection tasks for continuous strip products with a unique and most complete product portfolio. Our goal is to provide advanced solutions along the entire steel production chain. Hundreds of successfully installed systems confirm the benefit of many years of experience and technological competence. Whether it be casting, hot or cold rolling, pickling, annealing, galvanizing, coating or the finishing process – all are covered, as well as end products such as rails.

READ MORE

ไทย

ไทย