In 1975, Microsoft launched in the United States and the first personal computer, the Altair 8800, hit the market. The same year, Arjan Smit and Thijs Aarts, a creative inventor, were working together on another innovation in a creative R&D team at a large coffee roaster.What would happen if we could adapt our original idea to develop a machine that would measure and test other products highly accurately, a machine that would always work and never malfunction? Wouldn’t the whole packaging industry line up to adopt such a piece of equipment?This is how Arjan Smit established Oxipack Leak Detection in 2010, Non-destructive Leak Tester. We can offer stand-alone, custom made and in-line testing.Application is available for Rigid Packaging (CAN), Flexible Packaging, Vacuum Packaging, Bottles & Caps Industries: Food, Pharmaceutical, Cosmetic and others

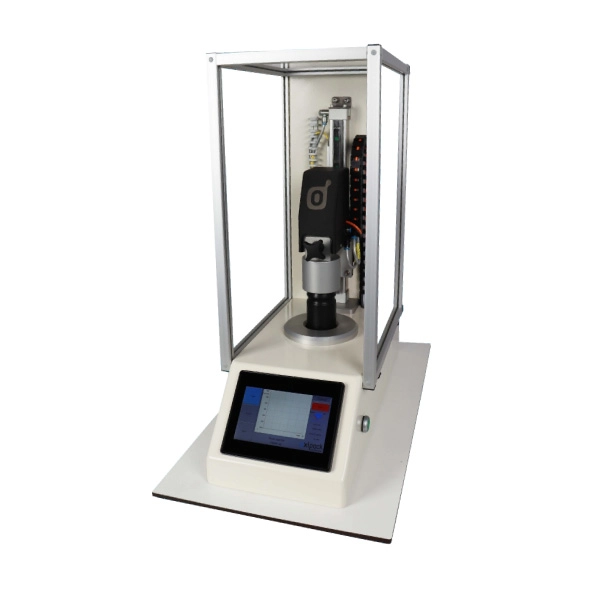

Rigid packaging

How do you test rigid airtight packaging for leaks? We have developed different type of leak testers for rigid packaging containing air or inert gas, which embrace the shape of the packaging as closely as possible. These packaging materials don’t bend or stretch like flexible packaging.

The rigidity offers extra support and structure for products. Common rigid packaging materials include tin/steel cans, glass jars, cardboard boxes and plastic bottles. Oxipack provide the non-destructive method of leak test.

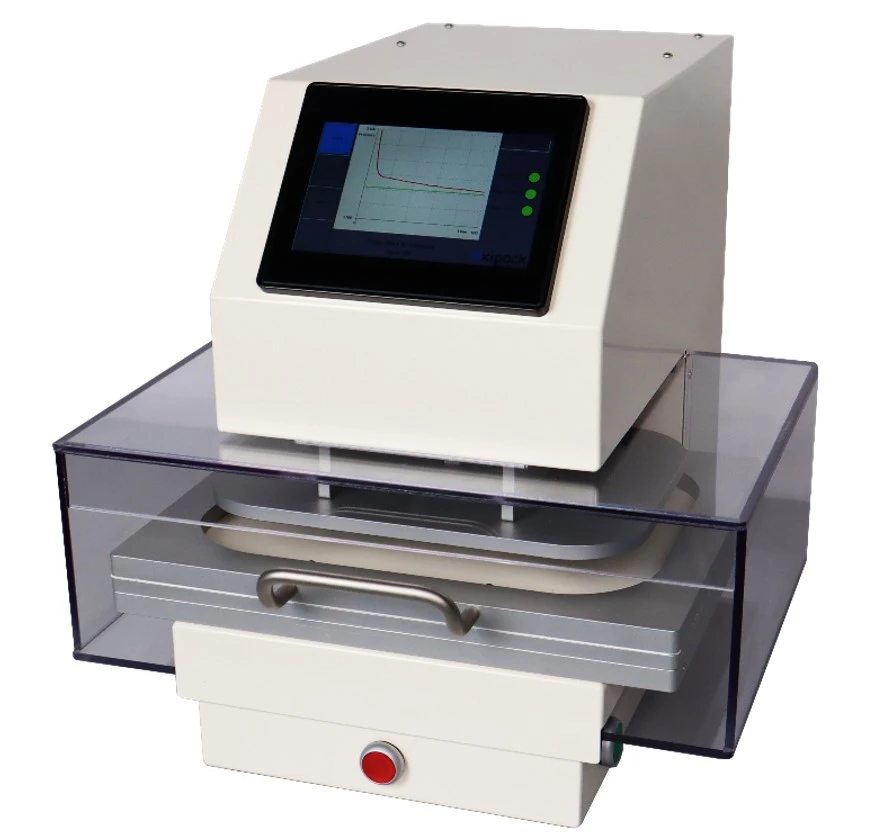

Flexible Packaging

Leaking product packaging is the worst nightmare of every product owner. Especially if these leaks cannot be detected before the end user receives the product.

At Oxipack, we have multiple leak testers for flexible and vacuum packaging. They have been specifically developed for off-line sample testing of flexible MAP-packaging. By systematically testing for leaks, you minimize the percentage of leaking packaging, avoid complaints about packages that are not sealed properly and reduce food waste.

At Oxipack, we have multiple leak testers for flexible and vacuum packaging. They have been specifically developed for off-line sample testing of flexible MAP-packaging. By systematically testing for leaks, you minimize the percentage of leaking packaging, avoid complaints about packages that are not sealed properly and reduce food waste.

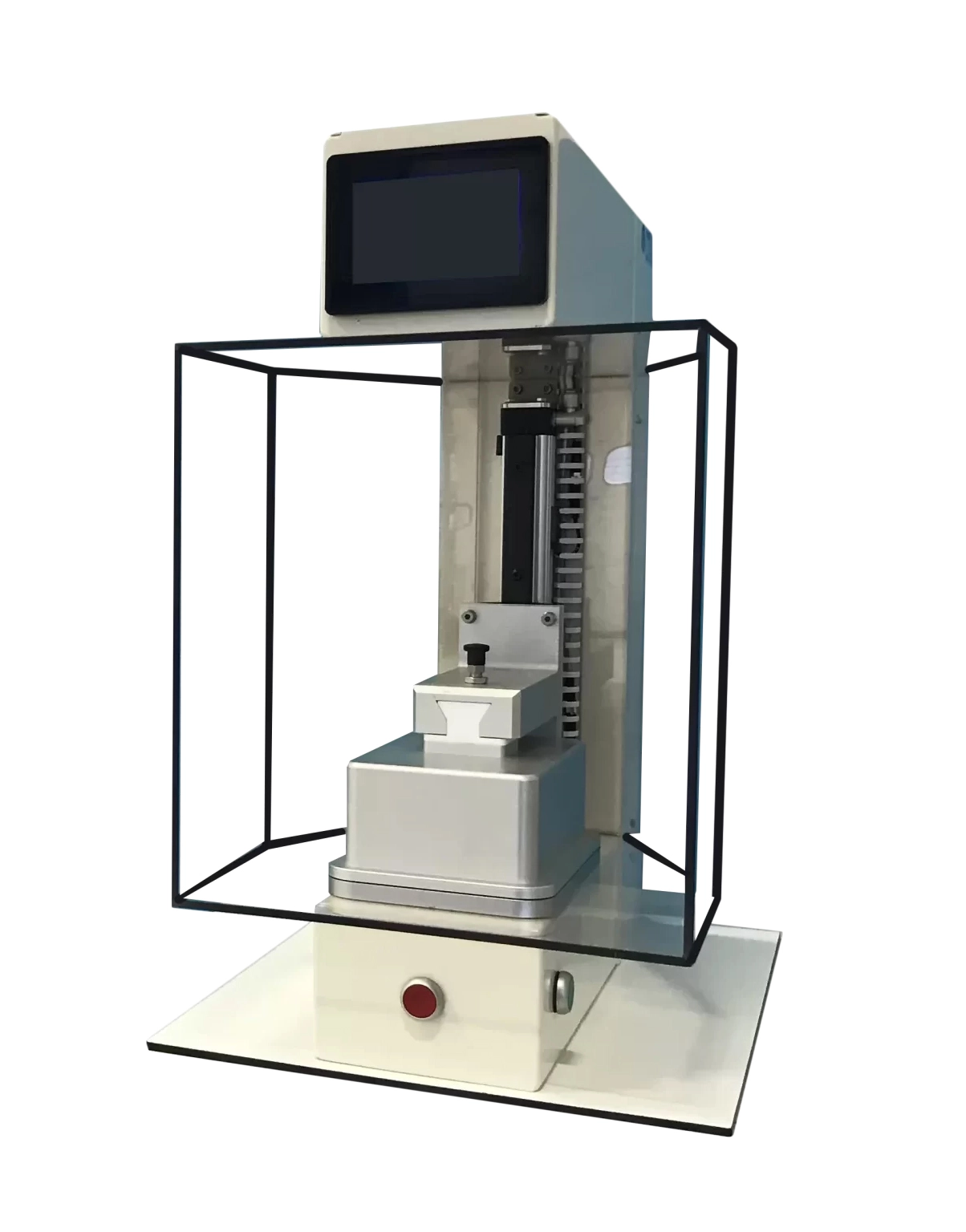

Bottles & CAPS

Your bottles or caps are leaking…not a pleasant thought and something that could pose a threat to your entire production line. Just imagine a leaking bottle of syrup in your chain… To test a bottle or cap for leaks, it is not always necessary or even possible to test the entire package for leaks. It might be sufficient to test only the top parts of the package: the cap, ring pull or seal. Is this part really airtight and leak-free? Oxipack develops special testing equipment for detecting leaks in the top parts of your products. It is available both single and multi-testing solution.

Vacuum Leak Tester

Vacuum packaging is a popular type to preserve freshness and quality of a variety of products in the food, pharmaceutical and electronic industries. However, vacuum packaging is only effective if the packaging is properly packaged and free from leaks. How do you ensure and guarantee leak-free vacuum packaging? By using a vacuum leak tester, you can check the integrity of your vacuum packaging and identify any leaks present in it.

Container Closure Integrity Testing

Container Closure Integrity Testing (CCIT) refers to the process of evaluating the tightness and sealing effectiveness of packaging systems, specifically containers, to ensure that the contents inside remain protected and unadulterated. The CCIT testing process is critical in the pharmaceutical industry, among others. Where product safety and efficacy are of the utmost importance.

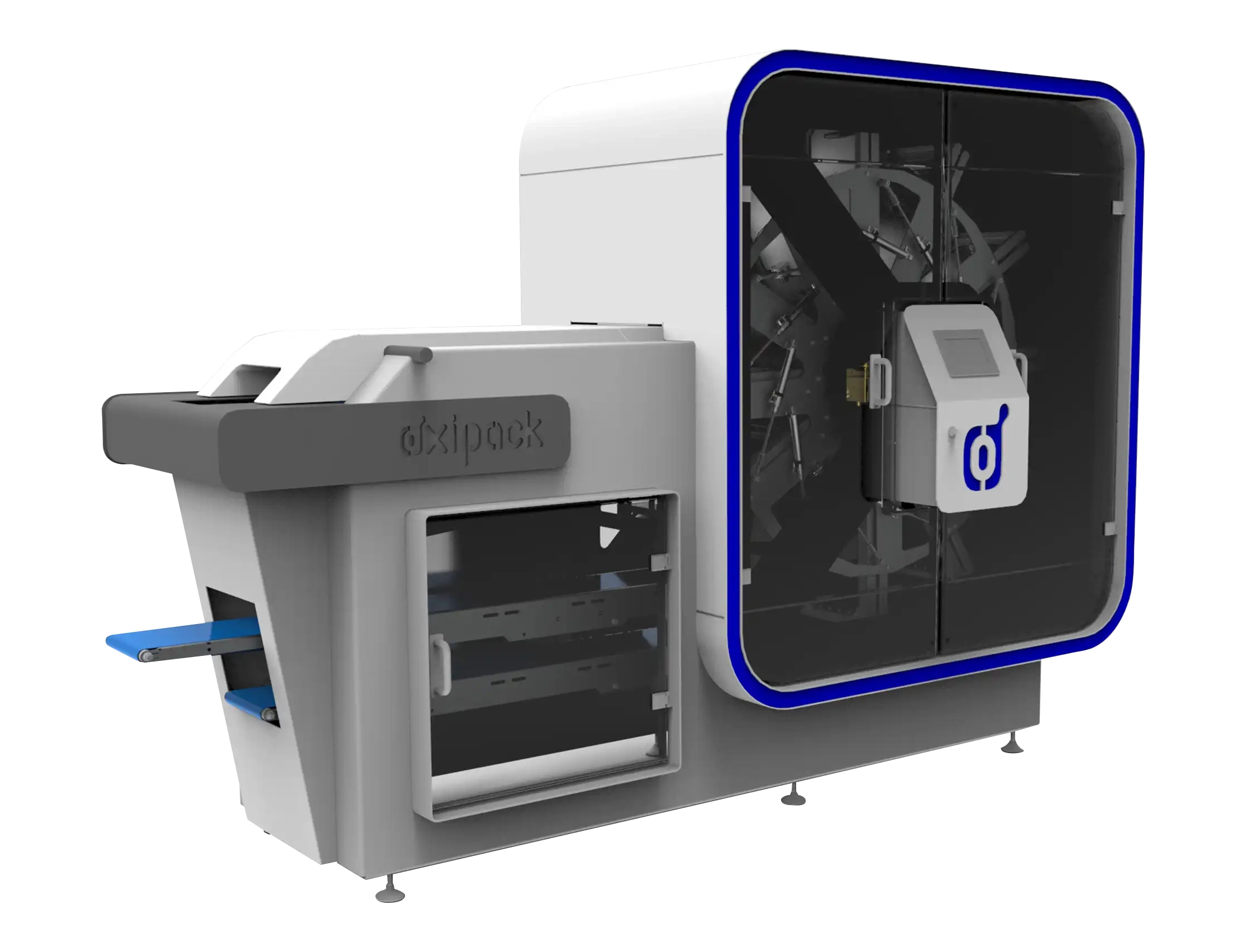

IN-LINE Leak Detection

Oxipack develops in-line leak test solutions that can be seamlessly integrated into your packaging production line. We provide fully automated systems to check your complete production line for leaks. However, it is also possible to do sample testing, for example, every one in sixty packages.

Head Office :

107/69 Moo 6, Khu Khot, Lam Luk Ka District, Pathum Thani 12130

E-mail : [email protected]

Mobile: Office 02-1026862 Sales 086-7888414

Line : @unisyntech

Facebook : Unisyntech Packaging Solution.

ไทย

ไทย