Cevolani Italia is a new organization that will keep on developing our products combining the traditions and the technical know. We are aiming not just to withhold but to improve our well-known name as reliable and efficient partner. Our mission is to provide Total Customer Satisfaction and Cevolani prides itself as the new solution provider for the can making industry.

Can Body Line

End Line

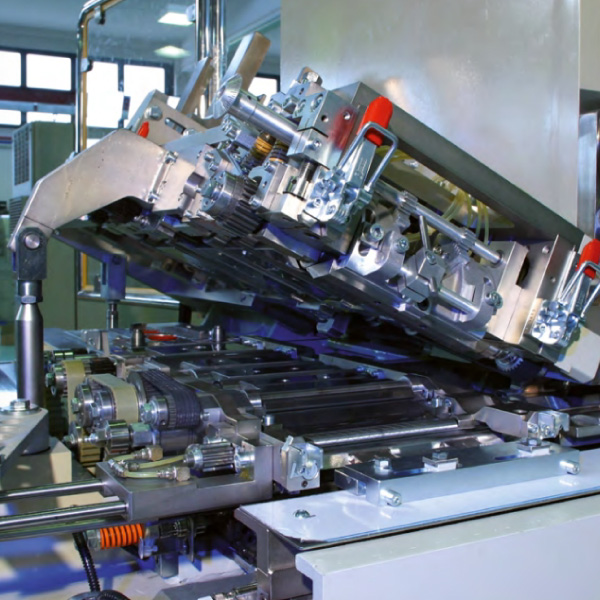

Stand Alone Machines

The Stand Alone Machines are Automatic Vertical Beader, Automatic Vertical Parter, Automatic Vertical Necker Automatic Vertical Flanger และ Automatic Vertical Seamer

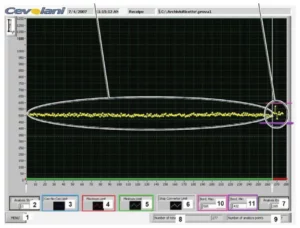

Cevolani Welder Monitor

Cevolani CONE Tester

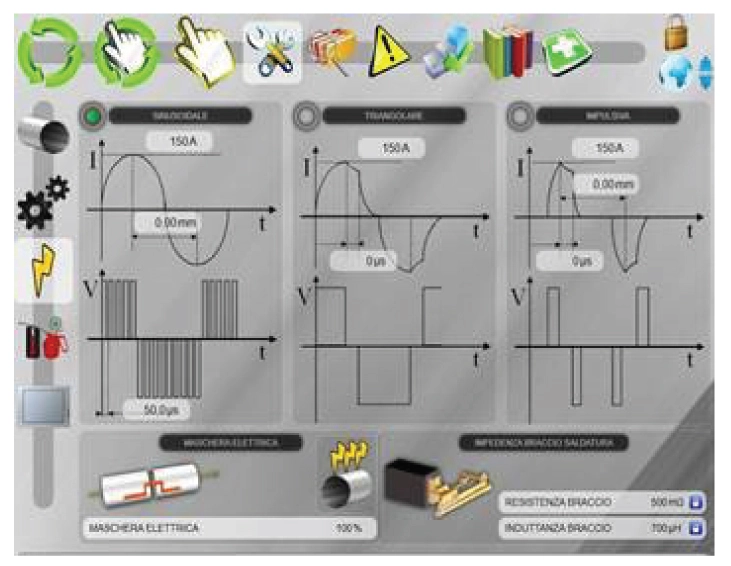

The can tester PSE 474 is used to check the mash seam of can bodies produced with the electro-welding machines. The tests, which can be carried out with that device, are of the mechanical type and are executed in order to check whether the can bodies are perfectly welded. The can tester is very important both in the phase of welding machine setting up and in phase of production. Generally the checkings are carried out with the sampling method, i.e. by picking some samples from the line production.

The main tests carried out on the can tester PSE 474 are the following:

1) Stretch test through a ball pressed against the welded seam and pneumatically dragged along it. This test of the mash seam can be carried out by applying the force from inside to the outside of can body or vice versa.

2) Overturning test through a profiled pad which is introduced into each of the ends of can body.

3) Flaring test through a conical pad introduced into an end of can body.

ไทย

ไทย