The expert engineers at CMC-KUHNKE have been at the forefront of quality control within the metal packaging arena for over 50 years. If you need to inspect the quality of a metal container within the food, beverage, or aerosol industry, we can offer you a variety of solutions. We have the gauges, testers, and software to reduce the cost of production and increase the efficiency of your canning and bottling processes. Thailand is the important market in South East Asia. We have customers both can makers and can packers.

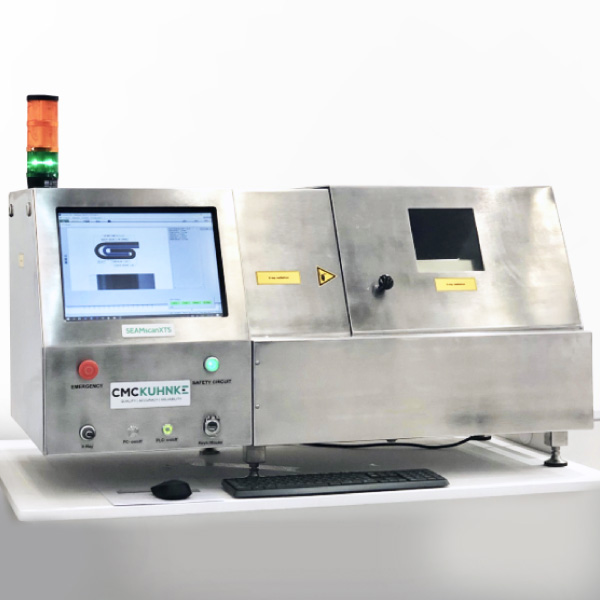

read moreSEAMscan XTS III

The new 3rd Generation XTS is a stand-alone measurement system that provides

non-destructive, double seam inspection for round cans (aluminum or steel). The gauge performs both non-destructive cross-sectional measurements and a 360° tightness scan. The system provides faster inspection results, and reduced labor costs. The most important purpose for this machine is “save cost” in long term usage.

SEAMscan SPC System

SEAMscan SPC System is an affordable, high-resolution tool for double seam inspection and measurement with SPC reporting.The system designs integrated Multiplexer for connecting up to 6 additional hand gauges. It can measure the seam less than 1 second.With 2500+ install world wide, we proud to be the BEST for double seam inspection. Thailand is the one of the most important market for CMC-KUHNKE, we have installed 50+ set to the can makers and packers, universities and government institutions

read moreSEAMsaw

SEAMsaw has more than 6 designes supporting 3pcs, 2pcs, Aerosol, General can and plastic cup. CMC-KUHNKE provide 2 types: manual and automatic system depend on the customer’s requirement.

read more

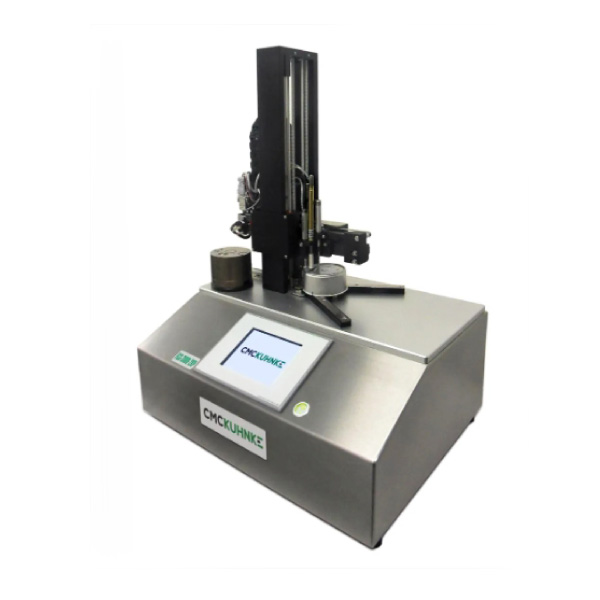

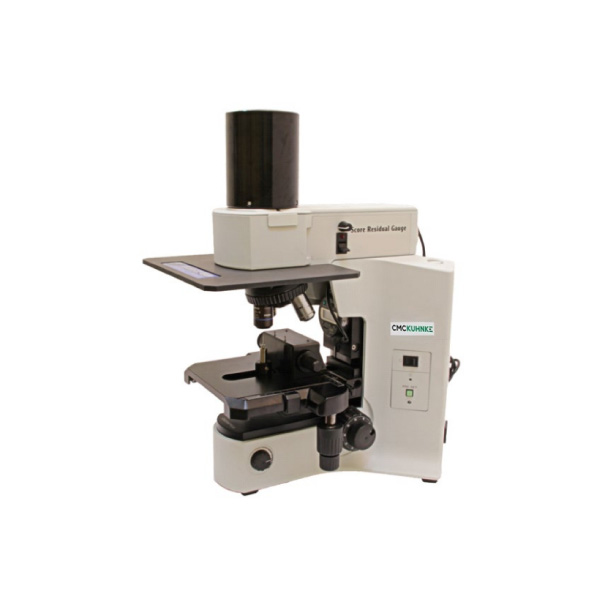

Score Residual Gauge

The SRG-4000 is highly repeatable and accurate gauge for measuring the score residual on easy open ends. Laser detection allows for accurate focusing on the score every time, giving accurate objective data. It is the perfect tool for the end maker and works with any end type (steel and aluminum, all sizes and shapes) The gauge come with the software needed for measurement as well as databasing of images, profiles and SPC report

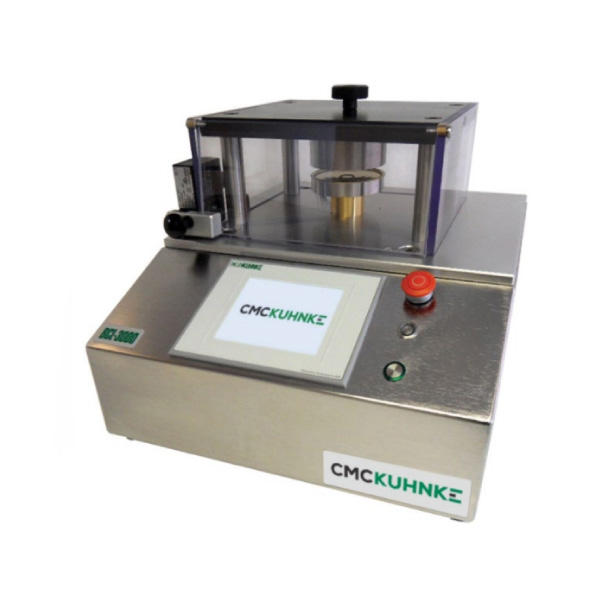

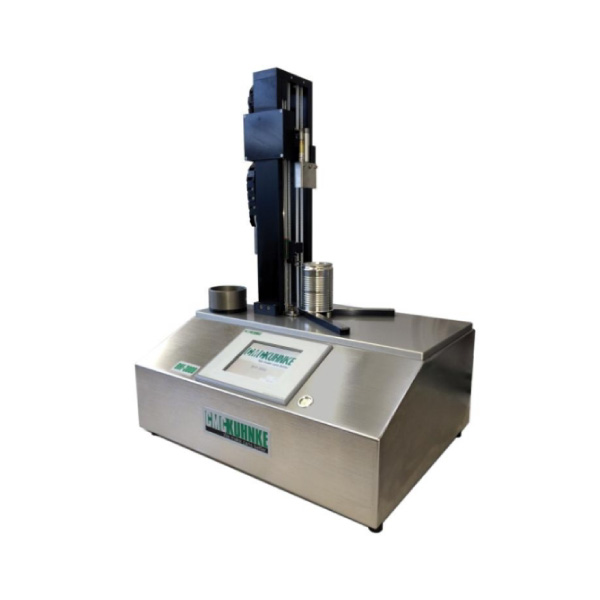

read moreTin Coating Thickness Measurement

“The STM-9000 provides accurate tin coating thickness (tin plating analysis) using the Windows™ operating system. It is a computerized coulometric metal thickness gauge for tin plated steel. The system uses new electrolytic/coulometric hardware and software. These coulometer cells are used by the STM-9000 to inspect the tinplate samples and perform thickness measurement testing on the tin plated ferrum.The operator inserts the metal sample (strip, or actual sample – coated with tin) into the cell. Electrolytic fluid fills the cell and the cell is closed. Next, the measurement process can proceed, with top only, top & bottom or 3x top and bottom measurements. Profiles are presented for each of the tin plate steel measurements. The gauge come with standards form built-in tables (e.g., ASTM, EURONORM, ISO, BSI)

read more

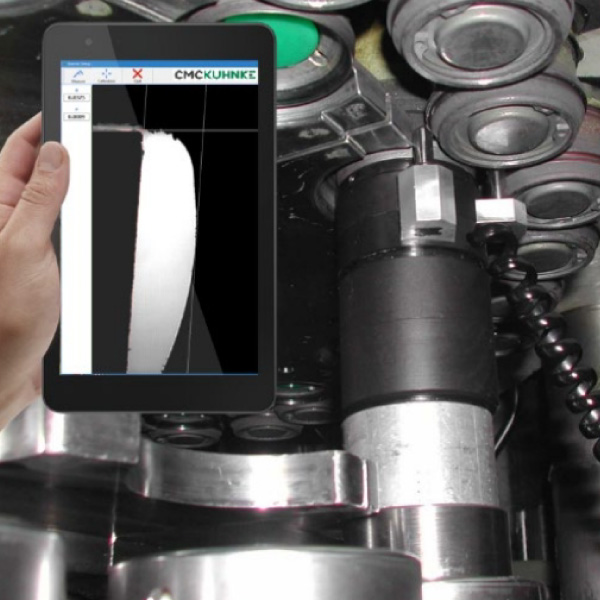

Clearance Gauge

The SCG-2000 is an easy and accurate solution for setting up your seamer. The camera takes the guesswork out of setting up the seamer by automatically measuring the seamer clearance and thickness. By minimizing downtime, this is especially useful for setup during changeovers and for daily use to make adjustments as the seamer warms up. The Clearance and Thickness Gauge not only quickly and accurately sets up the seamer and fixes issues, but also makes sure all seamer heads are running perfectly and are identical to each other. The SCG-2000 is suitable for food & beverage fillers of all sizes. The gauge comes with all the software needed for measurement as well as databasing of images and a suite of reporting and SPC. The gauge connects directly to any PC via USB

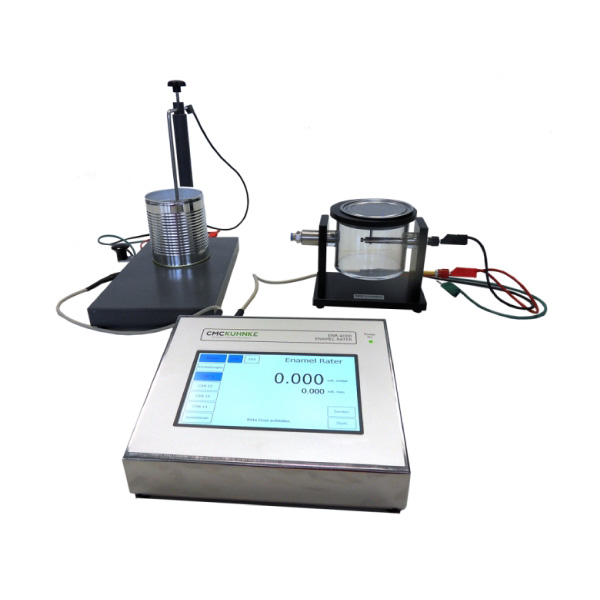

read moreDigital Enamel Rater

The ENR-4000 Digital Enamel Rater is a complete redesign of the industry leading (CMC-KUHNKE) Enamel Rater. It tests the coverage of the enamel coating inside food and beverage cans and ends. It accurately and quickly measures the Enamel Rating and Lacquer Permeability. The Enamel Rater ENR-4000 is the new standard for porosity measurements. A high-precision instrument with a large TFT display that can be switched on with a graph of the current measurement.

read more

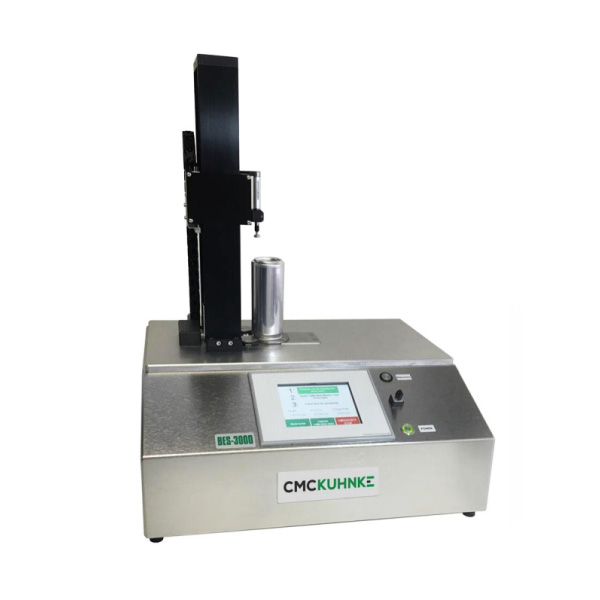

End Measurement Gauge

The Semi-Automated, multi-diameter End Measurement Gauge provides automatic measurements for every characteristic of the can end. With self calibration, the gauge is more accurated than using hand gauge or others. It can rotate the ends automatic with maximum 20 positions of measurement. It will spend only 30 seconds to measure 4 positions of the end. With PLC control, it can measure the end even the PC is damaged from virus or software crush. We have been trusted by end makers using it more than 15 gauges in Thailand

read more

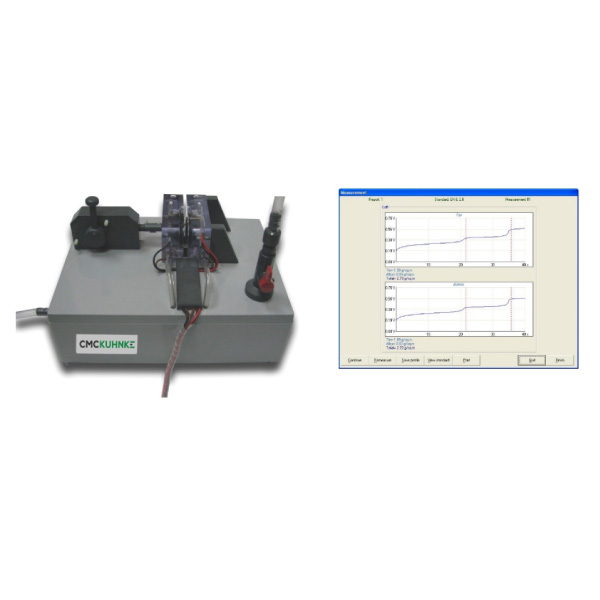

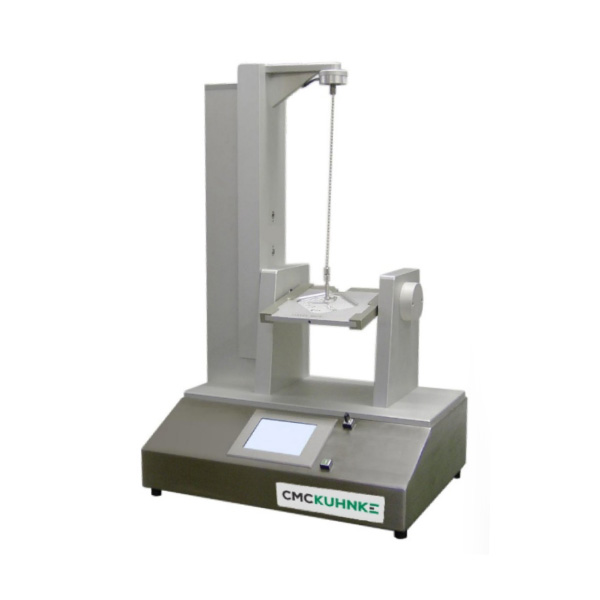

Pop and Tear Gauge

The Easy-Open End Pop & Tear Tester checks the force required to pop and tear, Tab-strength, and L-Rotation of Easy-Open Ends (EOE). It can be used with round,non-round and easy peel. Depending on the holder, ends of different diameters can be inserted and the electronically controlled force movement pre-programmed.The gauge determines the pop and the maximum tear strength and recalls both values in the display after the test is finished.The gauge provides fixed built-in basic test procedures, which can be customized to your requirements. The SPC Software can generate the graph showing in the report. Precision made parts and sturdy design ensure years of reliable operation.

read more

Bead Height Flange Gauge

The bead/height/flange gauge combines the functions of three essential gauges for objective, accurate, and repeatable measurements. Its solid, fixture-based design,v-block positioner and automatic operation make it easy for operators to feel confident in their readings, regardless of their quality assurance experience.With the resolution 1 micron from Heidenhain sensor, we claim to be the most accurate of bead/height/flange semi-auto inspection system.An integrated microprocessor allows the gauge to be pc-independent; eliminating any potential downtime due to computer related issues. Data may also be transferred directly into visionary QC or other data acquisition software.

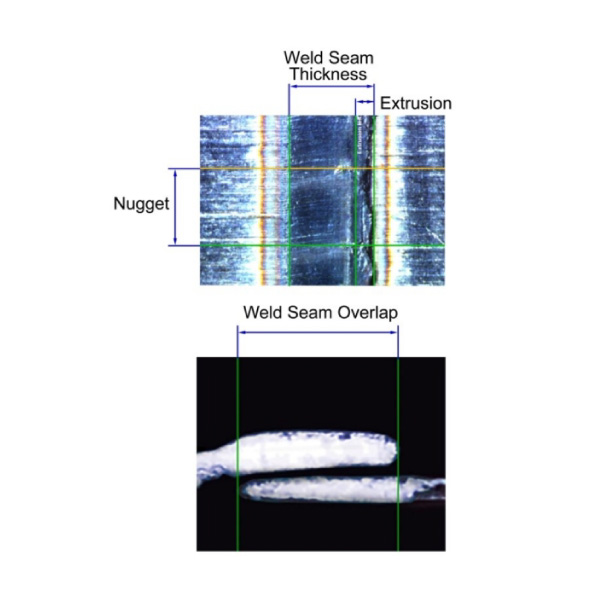

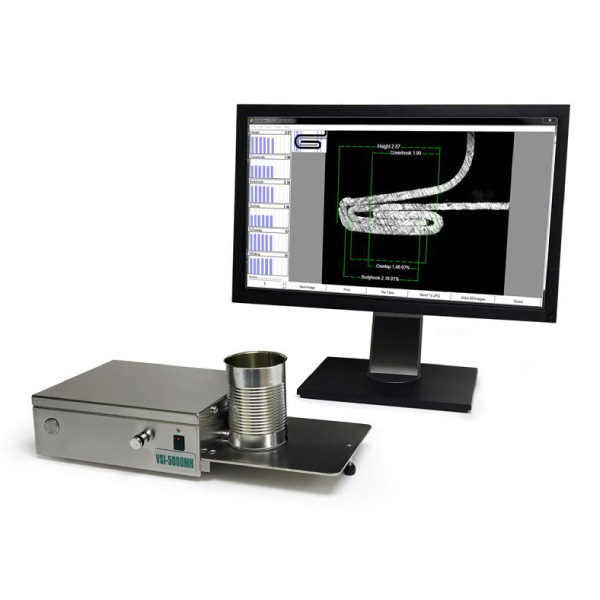

read moreDigital Video Microscope

The Weld Seam Evaluation System provides computerized measurement for measuring Can Welds and Side Seam Overlap. The system includes WELDview Software and a Digital Video Microscope. WELDview 6.0: The latest version of CMC-KUHNKE’s weld evaluation Software provides the benefits of high-accuracy,on-screen, computerized measurement to Side Seam Overlap Evaluation.

“Measures: Weld Seam Overlap, Weld Seam Thickness, Weld Fillet Length, Weld Fillet

Width, Extrusion and Nugget”

Body Blank Gauge

Ensure accurate slitter setups with the High-Precision Body Blank Gauge 2HDH for can making. With the help of a linear slide and Heidenhain sensor combination,and another Heidenhain sensor for the angle measurement, this high-precision digital gauge achieves a constant measuring force allowing for accurate,repeatable, and user-independent Blank Height, Blank Width and Body Blank Squareness measurements.

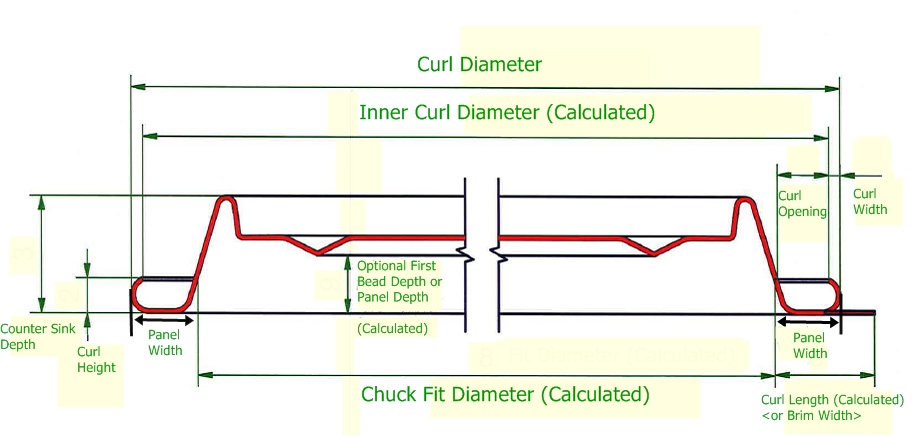

read moreManual Gauge

Manual Gauges are available for Steel, beverage, general and aerosol cans. Please contact us for more information.

read more

ไทย

ไทย