CEPEDA have since 1975 been Europe’s foremost machinery and solution supplier for drawn, shells, ends and twist off caps. MELTOG has beenproducing machinery for the decorative metal packaging industry since 1950. In 1998, MELTOG bought the Billoway twist off cap company from Linpack

Together, both companies make Europe the leading continent for the manufacture and supply of this type of equipment. To build on this reputation further and ensure development in this key sector of the packaging industry, both companies have combined their expertise to form a joint company ensuring that both new and existing customers enjoy an unparalleled level of customer service and the supply of turnkey and stand-alone equipment of the highest quality and reliability.

Under this new venture called CEPEDAMELTOG, the engineering takes place in the UK with manufacturing, assembly and spare parts being supplied from Meltog’s manufacturing facility with new sales, after sales, finance and administration being managed from Madrid.

Sheet Feed Press

With tonnages ranging from 20 tonnes (200kN) to 80 tonnes (800kN), with both geared and ungeared options, the CepedaMeltog range of sheet feed presses comprise a double frame arrangement which is fabricated and fully stress relieved prior to machining. Crankshaft position is continuously monitored by an absolute encoder and a monitored overload system is also included as standard. The press slide is precision guided with an industry leading 8 face pre-loaded roller bearing arrangement. The company further offers an industry leading rapid die changeover system that has been designed to be both straightforward and rapid using a SMED principles.

read more

Strip Feed Press

This machine is suitable for producing any kind of ends such as round, oblong or oval, any kind of cup or drawn body components with the option of either a single or a double die.

read more

Redrawing and Trimming Press

Double frame press with a transfer feeding system and equipped with two stations per lane and allows up to four lanes; this press is suitable for redrawing and trimming operations.

Trimming Press

Trimming Press is available for C frame inclined, or double frame. The maximum number of strokes are 220 piece / minute

read more

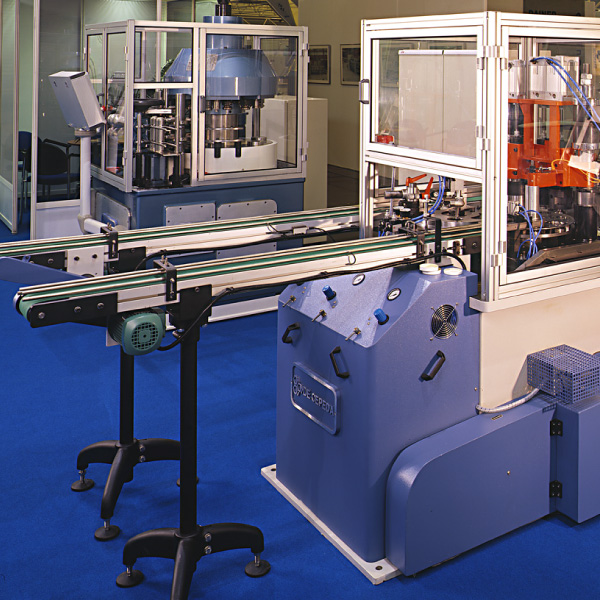

CEPEDAMELTOG

Turnkey Production Line for Aerosol Tops and Bottoms, The CepedaMeltog transfer system, with one transfer press and a dual lane tool, can produce up to 400 tops per minute. The sheet feed press will be equipped with 3 out blanks tooling working at 150 cpm, to correctly feed the transfer press at full speed a buffer or a circulating accumulator is included for blanks between 2 presses. We can always offer the option of one lane tool in the transfer press for an output of 200 cpm, approx. 12.000 tops each hour.

Twist Caps Forming

The twist caps forming units are under-cranked, vertical bridge presses, equipped with fully synchronised with twin indexing rotary tables and liner The maximum output is 1600 caps / minute

read more

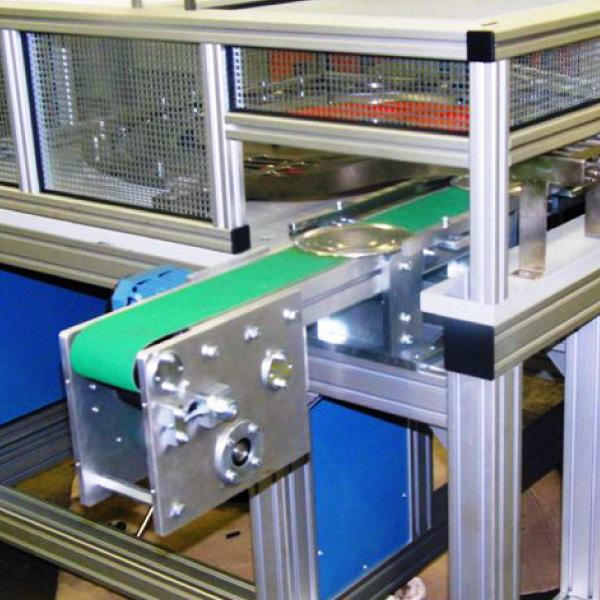

Curling Machines

Single or double curling machines suitable to produce round ends or non-round ends.

read more

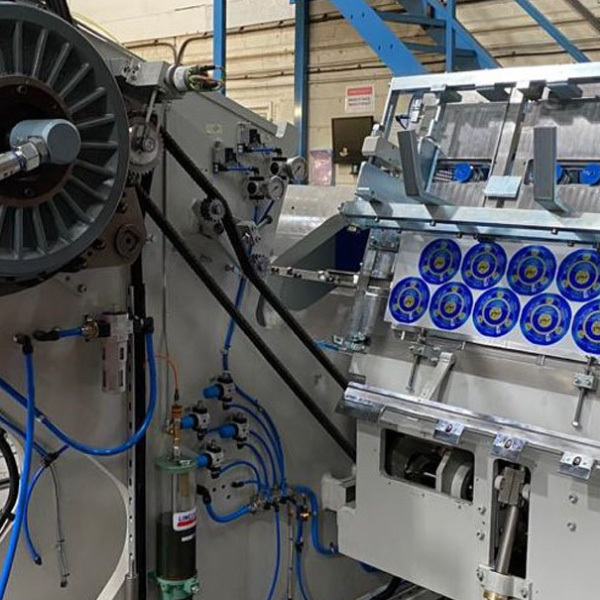

Liners

Suitable for any type of rounds tinplate ends and aerosol tops and domes or twist caps. It supports the application of water or solvent based compound. Tinplate and special version for aluminium. Max output is 800 cpm

read more

Head Office :

107/69 Moo 6, Khu Khot, Lam Luk Ka District, Pathum Thani 12130

E-mail : [email protected]

Mobile: Office 02-1026862 Sales 086-7888414

Line : @unisyntech

Facebook : Unisyntech Packaging Solution.

ไทย

ไทย